Aluminum Frame for Double Sided LED Light Box Poster

Place of Origin:

Guangdong China (Mainland)

Grade:

6000 Series

Temper:

T3-T8

Application:

Decorations

Shape:

frame

Alloy Or Not:

Is Alloy

Precision:

+-5%

Surface Treatment:

Mill finish, powder coated, anodized, electrophoresis, Polishing

Thickness:

0.65mm for sliding, 0.8mm for casement, or Customized for aluminum

Machining:

High Precision CNC Machining

Deep Process:

Precise cutting, drilling, milling, fabricating, punching

Product Description

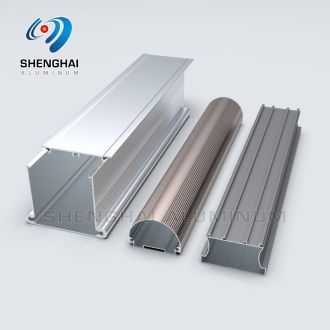

Aluminium frame for led light box has the advantages of strong, lightweight, easy to process and antirust. What’s more, the aluminium frame could help the LED to dissipate heat, ensure the LED to work stably and prolong the LED lifetime.Types of aluminum profiles for light boxes

Corner light box aluminum profile;

Curved light box aluminum profile;

Ultra-thin light box aluminum profile (general wall thickness 0.8mm);

Electronic strip screen aluminum profile;

CCFL, EEFL and LED light box aluminum profiles.

LED light boxes are widely used in commercial center interior decoration, chain stores, company signboards, commercial centers, supermarkets, airports, stations, subways, banks, and large exhibition projects.

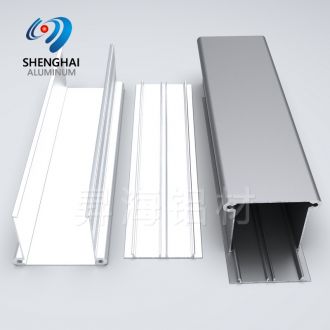

Aluminum LED light box frame features:

1. surface treatment: sandblasted, anodized bright silver or customized.

2. The outer frame material is made of AL-6063 aluminum profile, and anodized treatment is done to make the surface of the frame more beautiful. The use of high light guide plate material, so that the luminous efficiency of the lamp is higher.

3. aluminum frame is ultra-thin and fine, with good quality and no light leakage or gaps at the corners.

4. All the force surface is 2mm thick, which strengthens the strength of the profile and makes the profile suitable for different specifications of panel lights.

5. Easy to assemble, the power supply can be installed on the aluminum cover or external.

Product Application

Our Factory

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

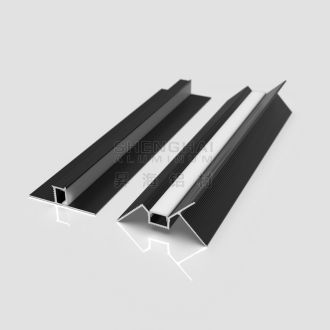

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Leave a Message