Thermal Break Profiles

A thermal break or thermal barrier is an element of low thermal conductivity placed in an assembly to reduce or prevent the flow of thermal energy between conductive materials. The opposite of a thermal barrier is a thermal bridge.

Thermal Break

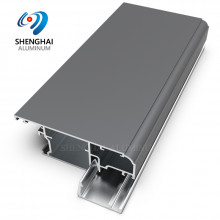

Foshan Shenghai Thermally Broken Aluminum Windows

Thermal Break

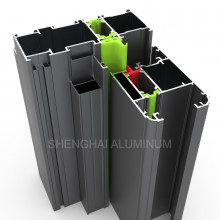

Thermally Broken Aluminium Window Frame Profiles

Thermal Break

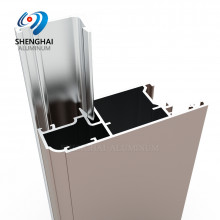

Thermal Break Aluminium Window Frame Profiles

Thermal Break

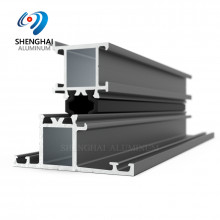

Foshan Shenghai Aluminium Thermal Break System Windows

Thermal Break

Thermal Break Profile Aluminum Frames for Windows

Thermal Break

Thermally Broken Aluminium Profile Frame for Windoor

Thermal Break

Thermal Break Aluminum Window Frame Section

Thermal Break

Thermal Break Profiles Extrusion Aluminum for Windows

Thermal Break

Thermal Break Aluminum Extrusions Section Frames for Windows

9R./P1

1

Leave a Message

Introduction to Thermal Break Profile Aluminum (Broken Bridge)

Thermally insulated broken bridge aluminum is also called broken bridge aluminum, thermally insulated aluminum alloy, and broken bridge aluminum alloy. The two sides of the thermally insulated aluminum bridge are made of aluminum, and the plastic profile cavity is used as the thermal insulation material in the middle. This innovative structural design takes into account the advantages of both plastic and aluminum alloy materials, while meeting various requirements for decorative effects, door and window strength and aging resistance. The insulated and broken aluminum-plastic profile can realize the three-way sealing structure of the doors and windows, reasonably separate the water vapor cavity, successfully achieve the equal pressure balance of air and water, and significantly improve the water tightness and air tightness of the doors and windows.With the development of society and the improvement of people's living standards, the living environment also tends to be high-grade, environmentally friendly, and the new concept product of the new type of thermal insulation bridge profile has also been introduced from abroad to China. Major companies engaged in the production of aluminum profiles are competing for the purchase of imported foreign thermal insulation bridge-piercing equipment. Domestic companies engaged in aluminum processing equipment have also developed thermal insulation bridge-piercing equipment. They all hope to introduce the new type of thermal insulation profile to the market. As an environmentally friendly and energy-saving product, customers generally accept it, but the production cost is higher than that of ordinary profiles. It runs through processes such as oxidation, spraying, and striping. Through the broken bridge connection, the oxidized silver white material can be connected with the color spray paint, and the sand fabric and the coloring material can be connected; the decorative feeling of the profile can be increased. The specific situation is explained as follows.

Advantage of Thermal Break Aluminum Profiles

1. Reduce heat conduction: the use of thermally insulated broken bridge aluminum alloy profile, its thermal conductivity coefficient is 1.8~3.5W/m2·k, which is much lower than ordinary aluminum alloy profile 140~170W/m2·k; it adopts hollow glass structure, and its thermal conductivity coefficient The temperature of 3.17~3.59W/m2·k is much lower than that of ordinary aluminum alloy profiles of 6.69~6.84W/m2·k, which effectively reduces the heat conduction through doors and windows.

2. Prevent condensation: the temperature of the inner surface of the profile with heat insulation strips is close to the indoor temperature, reducing the possibility of indoor moisture condensation on the surface of the profile due to oversaturation.

3. Energy saving: In winter, window frames with thermal insulation strips can reduce 1/3 of the heat lost through the window frame; in summer, if it is air-conditioned, window frames with thermal insulation strips can Reduce energy loss more and protect the environment: Through the application of thermal insulation system, energy consumption can be reduced, and the environmental radiation generated by air conditioning and heating can be reduced at the same time.

4. Good for health: The heat exchange between the human body and the environment depends on the temperature of the indoor air, the air flow rate and the outdoor air temperature. By adjusting the indoor temperature of doors and windows, it is not lower than 12~13℃, which has reached the most comfortable environment.

5. Noise reduction: The use of hollow glass structures with different thicknesses and a cavity structure of thermally insulated aluminum bridges can effectively reduce the resonance effect of sound waves, prevent sound transmission, and reduce noise by more than 30dB.

6. Colorful colors: After the surface treatment of anodizing and powder spraying, more than 200 different colors of aluminum profiles in the RAL color series can be produced. After rolling and combination, the insulated aluminum alloy doors and windows produce indoor and outdoor two-color windows with different colors .