Custom Aluminum Fabrication

We provide complete custom aluminum fabrication services to help transform your extrusion designs into fully finished products. With advanced CNC machining, customized cutting, drilling, tapping, bending, and professional surface finishing options such as anodizing and powder coating, we ensure precision, durability, and consistent quality for every aluminum component. Partner with us for efficient production, flexible customization, and reliable delivery across diverse applications.

Bending

Cold Bending Aluminum Extrusion Profiles For Lawnmower

Netherlands - Bending

Curved Extruded Aluminum Frame For Advertising Display

Auto Parts

Precision Cutting Aluminum Tube for Automotive Industry

Train Door

Black Powder Coated Aluminium Door Frame Profile for Train

.jpg)

Customized Parts

CNC Milling Anodized Aluminum Profile For Parts

handle

CNC Silver Anodized Combined Aluminum Handles for Europe

parts

Aluminum CNC Machined for Custom Industrial Aluminium Parts

CNC Parts

Germany CNC Aluminum Parts For Hyperspectral Imaging Camera

SH-DP-01

SH-DP-01 Custom Aluminium Box for Device

parts

Die Casting CNC Machined Aluminum Fix Joint Spare Parts

Iran

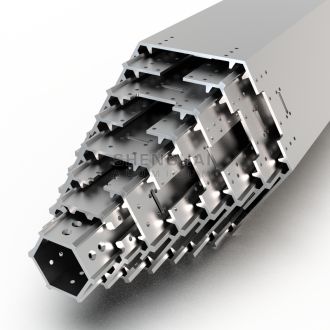

Iran Hexagonal Aluminum Telescopic Pole Profile For Telescope

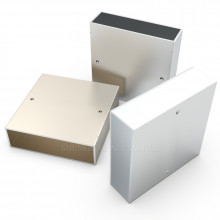

SH-DP-02

Powder Coated CNC Machining Extrued Aluminium Profile Case

Leave a Message

Custom Aluminum Fabrication Services

Delivering high-precision aluminum extrusion fabrication with complete machining, surface finishing, and assembly solutions. We provide one-stop service.Why Choose Our Aluminum Fabrication Services

As a professional aluminum extrusion factory, we provide complete fabrication capabilities to turn your designs into finished components. From cutting and CNC machining to anodizing and final assembly, we help reduce outsourcing costs and shorten your production lead time.One-stop processing from extrusion to finishing

Support for OEM/ODM customized parts

Strict quality control for stable performance

Fast prototyping and mass production flexibility

Full Machining Capabilities

We provide a wide range of mechanical processing services tailored for aluminum extrusion profiles:

Precise cutting to size

CNC milling and drilling

Tapping and countersinking

Punching and slotting

Bending / Curving

Welding for structural reinforcement

Materials: 6063, 6061, 6005, 6082 and other aluminum alloys

Supported Drawing Formats: STP, STEP, DWG, PDF

High precision with tolerance control up to ±0.05 mm (depending on complexity)

Professional Aluminum Surface Treatment

Surface treatment is one of the important processes in our aluminum processing. Through this process, we can provide customers with aluminum materials that meet their required color and profile hardness. We have a mature surface treatment production line, and these are some of the commonly used processes:Anodizing: Strong corrosion resistance, uniform colors;

Powder Coating: Durable finish, wide color selection;

Sandblasting & Brushing: Decorative matte or satin texture;

Electrophoresis: Premium coating finish for architectural products;

Polishing: Mirror-like, smooth, high-end appearance.

If you require any aluminum surface treatment solutions, please feel free to contact us.

Assembly & Value-Added Services

We take your products one step further:

Component assembly

Plastic & hardware fitting installation

Custom packaging and labeling

Laser marking/logos

Prototype sampling

This allows you to receive ready-to-install aluminum components — reducing workload and shipping costs.

Industries We Serve

Our aluminum fabrication services are used in:Building & Architecture – windows, doors, curtain walls

Furniture Systems – handles, frames, cabinet parts

Industrial Machinery – guide rails, structural parts

Electronics & Lighting – housings, LED profiles

Automotive and Transportation

We support customized projects across multiple international standards.

Quality Control and Inspection

Quality is ensured at every stage:Dimensional inspection with calipers & projectors

Hardness and surface tests

Strict process tracking

Final QC before packing

Certified materials and technical reports are available upon request.

Typical Aluminum Fabrication Workflow

Extrusion → Cutting / Machining → Surface Finishing → Assembly → QC → Packing → ShipmentWith stable supply and professional handling, your projects are delivered with consistent quality!

Case Showcase

Machined Aluminum Frame – CNC milling + anodizing + assembly

Decorative Trim for Furniture – precise bending + powder coating

Lighting Aluminum Profile – drilling + end cap fitting installation

.jpg)

Why Work With Us?

Over 15 years of aluminum manufacturing experienceAdvanced production lines and skilled engineering team

Competitive pricing from a direct extrusion factory

Fast response and quotation within 24–48 hours

We help you create aluminum parts with better performance and lower cost.

FAQ

1: Can you fabricate aluminum extrusion profiles based on my drawing?Yes — we support custom machining according to your 2D or 3D drawings.

2: What’s your MOQ?

We accept flexible quantities depending on the product; trial orders are welcome.

3: Do you provide surface treatment with guaranteed color consistency?

Yes, our anodizing and coating lines provide stable and repeatable finishes.

4: Can you keep my designs confidential?

Absolutely — NDA agreements are available for OEM projects.