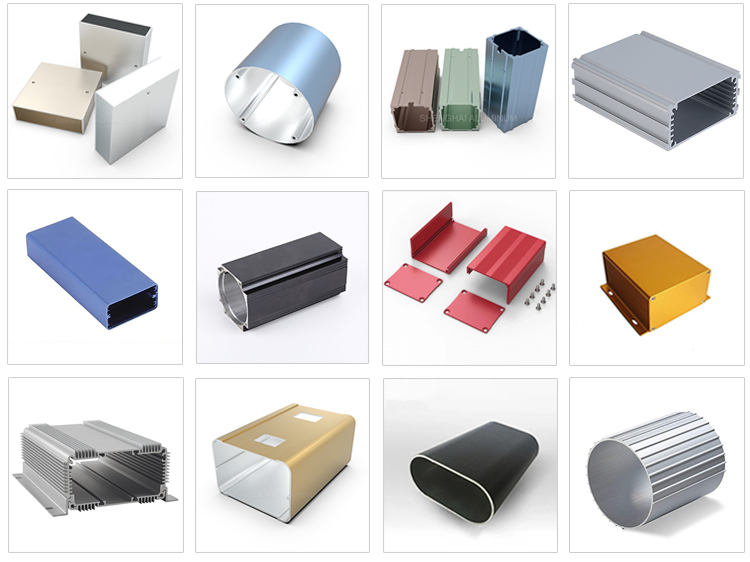

Extruded Aluminium Enclosure

China Extruded Aluminium Enclosure Manufacturer

Extruded aluminum enclosure box is widely used. China Shenghai aluminium enclosure is mainly used in radiator housing, electronic enclosure, power supply box, equipment enclosure, etc.Service We provide:

1. Professional technical team Suggestions improvement for you about your product drawings.

2. Professional quality inspectors to Ensure the quality and compliance of your products.

3. Professional staff to match custom colors for you,make samples for you if you need.

4. Professional die development capabilities.

5. Professional aluminum manufacturer experience, more than 11 years.

|

Request a quote |

How to extrude aluminum enclosure

Nowadays, the shells of many products are made of aluminum alloy, which is widely used in the enclosure of products because of its high strength, lightweight, good corrosion resistance and easy processing. However, it needs to be extruded in the production process to get the aluminum alloy shell.

1. Heat the furnace and put the aluminum rods in the furnace.

2. Heat the mold at the same time, and then put the mold in the corresponding mechanical position.

The mold will determine the shape of the aluminum enclosure.

3. Extruded profiles to form long materials for aluminum alloy shells.

4. Finally, the aluminum box is cut and processed according to customer requirements.

What deep processing can SHENGHAI provide for extruded aluminum housing

Shenghai Aluminum provides different processing methods for extruded aluminum enclosures, including:

Anodized surface treatment

Powder coating surface treatment

Electrophoresis

High precision CNC machining

Before anodizing, we usually process extruded aluminum case through sandblasting, brushing and polishing, and machining services.

Aluminum enclosure can applicate to rescue valuable instruments and electronic components from damage (aluminum box has the function of heat dissipation).

Printed circuit board (PCB) electronic enclosure

High fidelity amplifier case

Aluminum junction box

Electronic instrument

Electronic cable

Extruded Aluminium Enclosure for LED light aluminum extrusion enclosure for PCB

Communication equipment

medical equipment

Instrument case

Power converter

How to color Extruded Aluminum Enclosure

The aluminum alloy shell also has a formal coloring process. What are the specific coloring process of Aluminum extrusion enclosure.

1. Surface pretreatment

Using chemical or physical methods to clean the aluminum alloy shell is conducive to obtaining a complete and dense artificial oxide film.

The mirror or matte effect can also be obtained by CNC machining.

2. Anodizing

After the surface pretreatment of the shell, under certain process conditions, the surface of the shell is anodized to produce a dense, porous, and strong adsorption film layer.

3. Sealing

The gaps of the porous oxide film formed after anodizing oxidation are sealed so that the oxide film has anti-pollution, anti-corrosion and wear resistance. The oxide film is colorless and transparent and uses the strong adsorption of the oxide film before sealing. The adsorption and deposition of some metal salts in the film pores can make the profile's appearance show many colors other than the natural color. Such as: black, golden yellow, rose gold, etc.

The use of aluminum alloy is becoming more and more extensive, and the pursuit of colors in use is also becoming more and more diverse. The colored aluminum alloy shell has very good colors and can also meet customer needs.

1. low production cost and high-cost performance;

2. The production process is relatively mature and high-capacity;

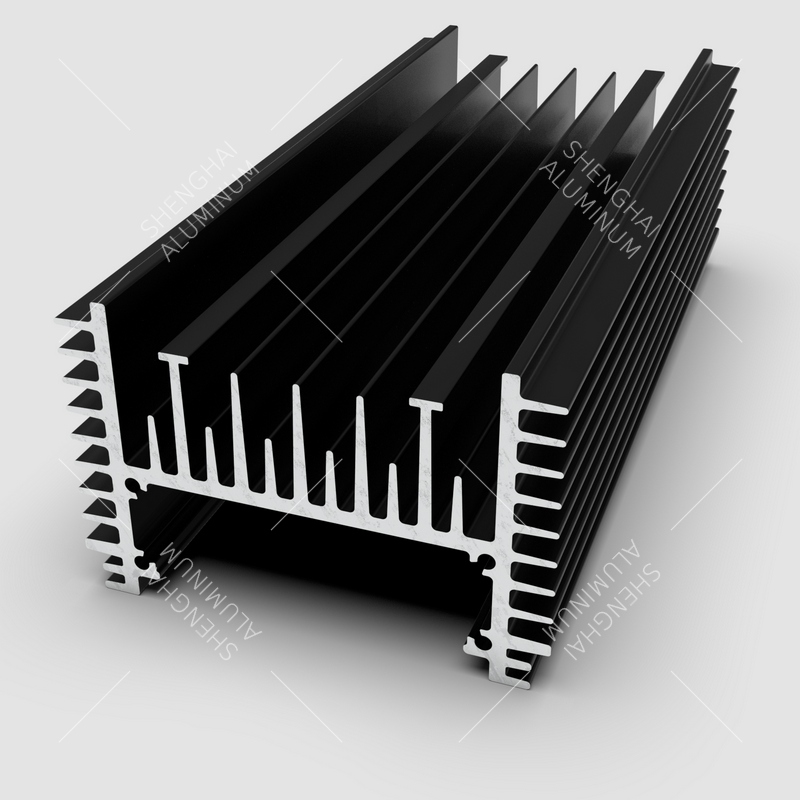

3. The aluminum profile has good thermal conductivity and good heat dissipation performance;

4. The aluminum radiator has good oxidation and corrosion resistance and good environmental adaptability;

5. Aluminum radiators are widely used in machinery, automobiles, batteries, wind power generation, construction machinery, air compressors, railway locomotives, household appliances, etc., due to their superior performance.

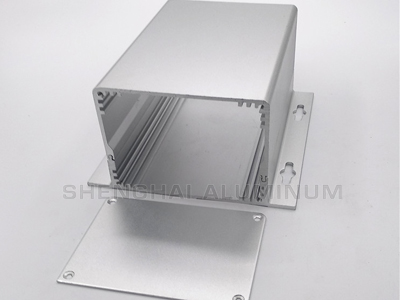

1. Safe to use, high pressure

Because the aluminum profile has good strength and rigidity, even in the case of thin thickness, it can accept sufficient pressure, bending force, tensile force and impact force, which can protect the internal components of the shell.

2. Simple device and convenient repair

Because the aluminum profile density is low and can be processed into various shapes, it is more convenient to assemble. Even if the surface is damaged, it can be repaired quickly.

3. Corrosion resistance and long service life

The aluminum alloy case produces a layer of the oxide film to protect the aluminum case.

4. Energy saving and consumption reduction, low use cost

Due to the excellent performance of the aluminum alloy housing, the service life of the aluminum housing is relatively longer than that of other materials, which can reduce the cost of use.

5. Good heat dissipation

The aluminum profile has good thermal conductivity, so aluminum extrusion heatsink is widely used in many industries.

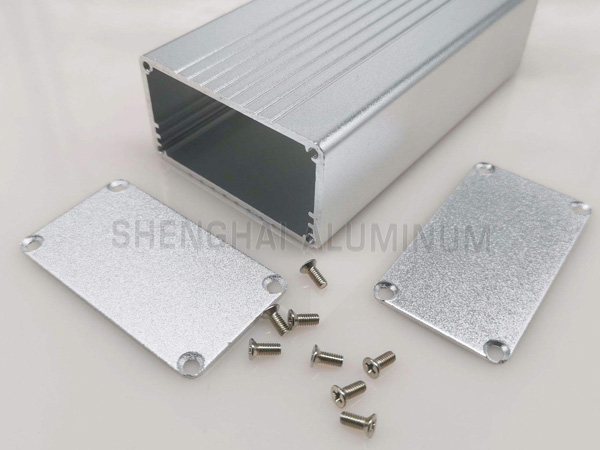

1. Does the Extruded aluminum enclosure have a regular size?

Yes, Shenghai has many standard aluminum housings.

2. Can the aluminum extrusion box size be customized?

Yes, our extruded aluminum enclosures are available in different sizes to meet your unique application requirements. Just tell us your size and you will get its squeeze.

3. Can Shenghai provide deep processing?

Yes, we can provide any deep processing. CNC machining aluminum enclosure (tapping, drilling, punching, etc.)

4. Can you provide aluminum enclosure box samples?

Yes, we can provide you with samples

5. Can Shenghai provide extruded aluminum enclosure accessories?

Yes, we can provide parts for assembling aluminum enclosure.