Glazed Aluminum Frame Curtain Wall Profile for USA

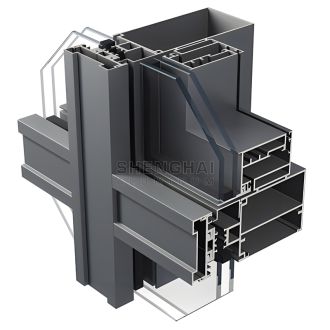

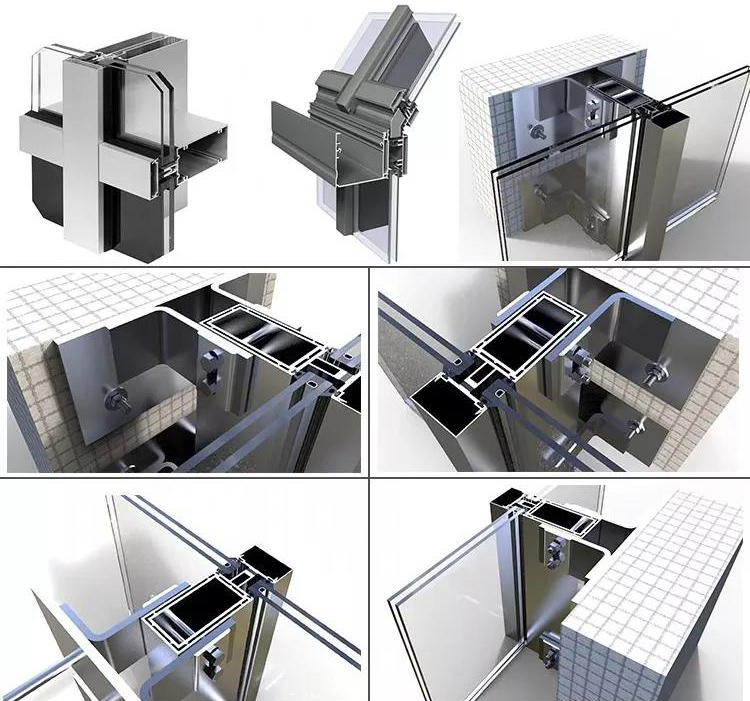

Aluminum profile curtain wall is a highly architecturally significant construction, mainly used in commercial buildings, covering small or large areas. Most buildings are aluminum frames with various industrial materials such as glass, composite panels, ceramics, marble, etc., above or inside.

Exterior and interior members are joined internally with injection-molded thermoplastic joints, providing complete thermal isolation and superior thermal performance.

Material savings of up to 15%

Faster project completion times

Cheaper than traditional pressure bar systems

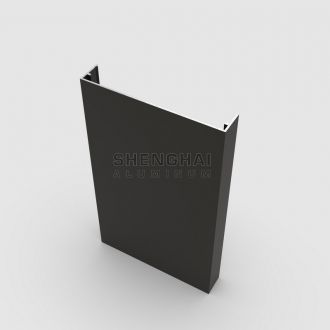

This curtain wall aluminum profile features a stick or panel mount with no exposed attachment fasteners. It can be used in captured glass or double-sided structural silicone glass configurations. This zone-sealed, pressure-balanced system offers superior performance and value.

We offer aluminum profile glass curtain wall solutions

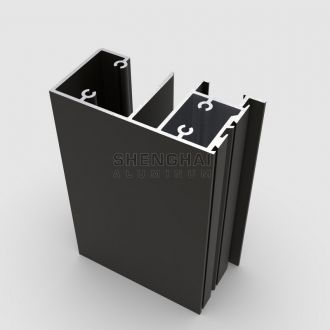

1.Curtain wall with visible frame

2.Curtain wall with hidden frame

3.Curtain wall with horizontal visible frame and vertical hidden frame

4.Vertical visible frame and horizontal hidden frame curtain wall

5.Unitized curtain wall

6.Curtain wall with thermal break

Of course, we can produce glazed aluminum curtain wall system in various finishes according to your drawings and samples. We also double-check the quality of our products to extend their life and achieve your satisfaction. Talk to one of our sales representatives to find the right product for you.

|

Material Grade: |

Alloy 6000 series |

|

Temper: |

T3-T8 |

|

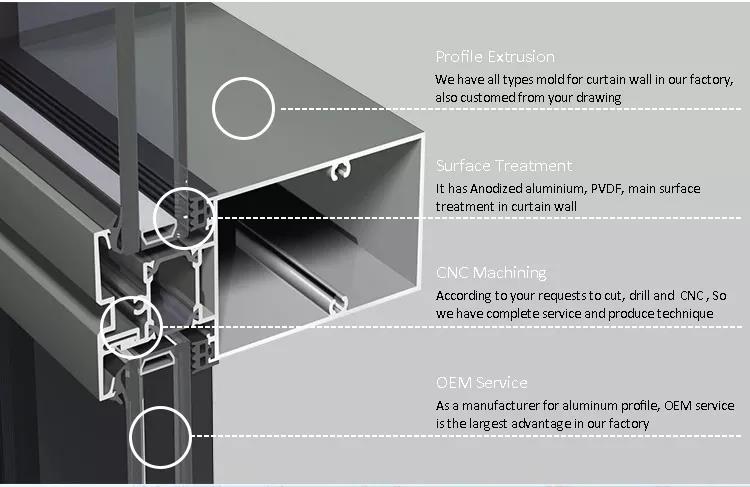

Technology: |

Aluminum Extrusion |

|

Surface Treatment: |

Mill finish, anodizing, powder coated, sandblasting, electrophoresis etc. |

|

Color: |

Silvery white, black, golden, champagne, dark bronze or according to your requirement |

|

Shape: |

Square, Round, Flat, or according to customers' drawings |

|

Deep processing: |

cutting, drilling, punching, bending etc. |

|

2D&3D Design: |

We can design for you according to your requirement and drawings |

|

Specification: |

A. Length: ≤6.7m; B. Normal Wall thickness: ≥1.0mm; C. Normal Anodizing thickness: ≥8µm; D. Normal powder coating thickness: 60-120µm; E. Tensile strength: ≥160mpa; F. Yield strength: ≥110mpa; G. Extensibility: ≥8%; H. Hardness(HW): 8-15 |

|

Packing details: |

1.EPE for each profile; 2. Wrap with shrink film exterior; 3. Packed according to customer request. |

Product Application

The main applications of aluminum curtain wall profiles in the construction industry are:

A. Building facades

B. Construction green buildings

C. Wall cladding

D. Building exteriors

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |