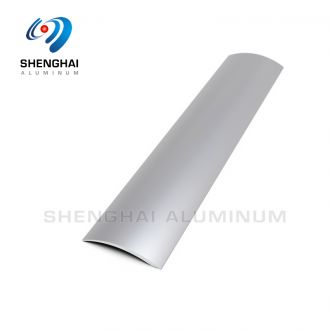

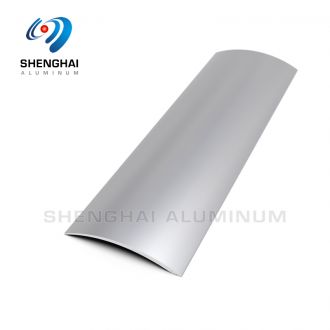

Aluminum Connection Threshold Floor Trim Strip for Finland

Place of Origin:

Guangdong, China (Mainland)

Grade:

6000 Series

Temper:

T3-T8

Application:

Decorations

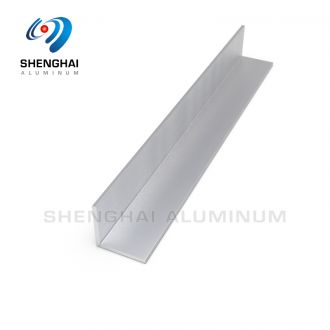

Shape:

Angle

Alloy Or Not:

Is Alloy

Brand Name:

shenghai

Precision:

+-5%

Surface Treatment:

Mill finish, powder coated, anodized, electrophoresis, Polishing

Thickness:

0.6mm-2.0mm

Machining:

High Precision CNC Machining

Deep Process:

Precise cutting, drilling, milling, fabricating

Quality Standard:

GB 5237-2008

Product Description

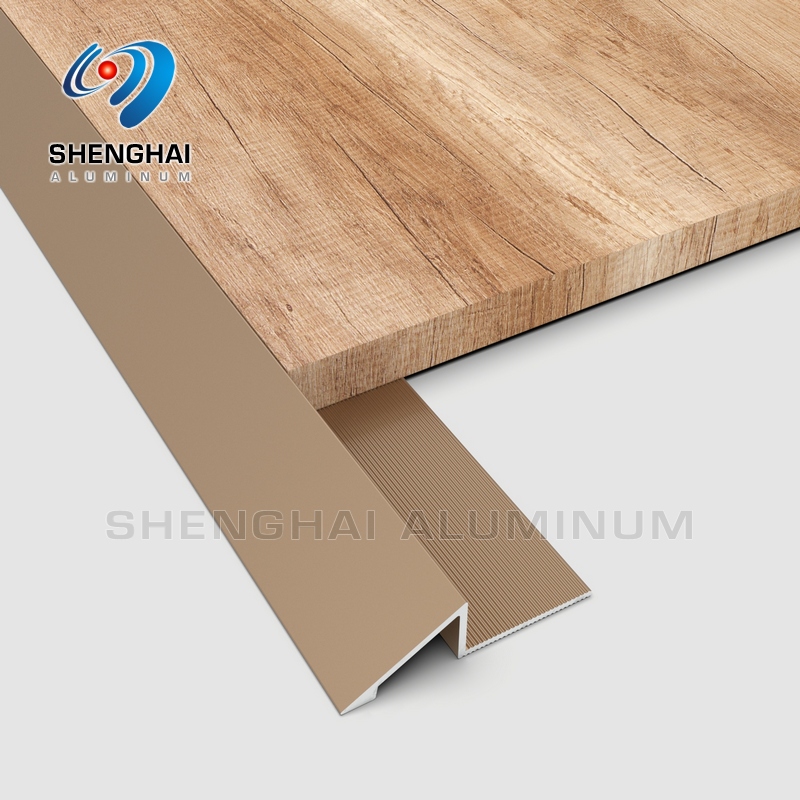

The aluminum threshold transition strip aims to bridge the height difference and provide a seamless transition between two different floor surfaces, such as tile to carpet, laminate to hardwood or vinyl to tile. This helps create a clean and professional-looking finish while also preventing trip hazards and protecting the edges of the flooring material from damage.Aluminum connection transition trims are often available in various profiles and styles to accommodate different flooring materials and design preferences. They can be straight or angled, with varying heights and widths to accommodate the different height differences between two floor surfaces. Some aluminum jointed threshold floor trim pieces have other features, such as hidden fastening systems or protective coatings, to enhance their functionality and durability. Of course, Shenghai Aluminum can customize a variety of aluminum trim strips for you. Please contact us today!

Aluminum edge trim strip plays a beautiful role in decoration. Aluminum edge trim is wall panel line, aluminum alloy line, edge trim, U-shaped strip, aluminum skirting line. Aluminum edge trims various building decoration materials such as aluminum trim for tile/floor/carpet, U-shaped strips, T-shaped strips, trimming strips, aluminum skirting lines, etc., can be customized.

Aluminum trim transition strip various building decoration materials.Our aluminium threshold trim strip create clean lines and protect the edges of your floor carpet cover,giving your project a slick,professional finish.

Service We provide:

1. Professional technical team Suggestions improvement for you about your product drawings.

2. Professional quality inspectors to Ensure the quality and compliance of your products.

3. Professional staff to match custom colors for you,make samples for you if you need.

4. Professional die development capabilities.

5. Professional aluminum manufacturer experience, more than 10 years.

Product Feature:

1.High quality aluminum alloy profiles, thickness 0.4mm-20mm or customized.

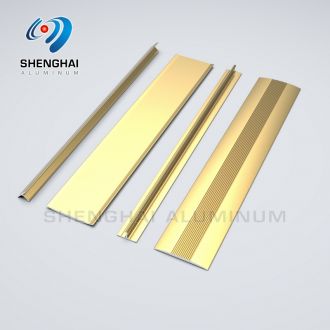

2.Color: Silver, Champagne, Bronze, Golden, Black, Wood grain, Sand coating, Anodized Acid and alkali or Customized.

Product Application

.jpg)

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Leave a Message