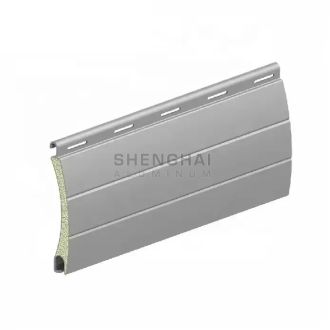

End Slat For Aluminum Roller Shutter

Model Number:

6061 6063 T5 T6

Color:

Customized

OEM:

Available

Free Samples:

About 1 days can be sent

Supply Ability:

1200-1600 tons per month

Payment:

T/T, L/C

Product Origin:

Foshan China

Shipping Port:

Shenzhen/Guangzhou/Foshan

Lead Time:

7-15 Days

Product Description

Normally, we improve the quality of aluminum roller shutters by applying a double powder coating to both roller shutter slats and end slats. This process enhances the durability of the roller shutter profiles. We create customized designs to provide you with the ideal roller shutter profiles, combining design and quality to help you increase the competitiveness of your roller shutters in the market.

1. Cutting using length, less than 3 meters per piece;

2. Making perforations on the slats;

3. Installing the accessories, eg: Sealing Rubber on the bottom guide rail or bottom slat, Side Clip or Plastic Cover at the two ends of general slat.

Specification

Customizing is available as you offer us the section drawings

Two kinds of profiles: non-thermo-break profiles and thermo-break profile

Surface finish: mill finish, anodizing, electrophoresis, powder coating, wood grain, PVDF

Property: sound isolation, heat preservation, saving energy

Colors: Brown, black, white, champagne, or Customized

Shape: Square, round, hollow, triangle, or Customized

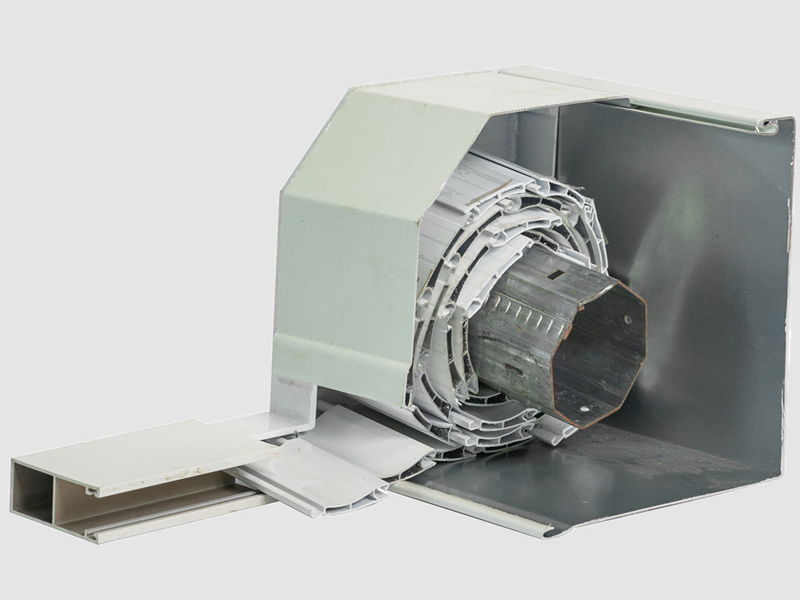

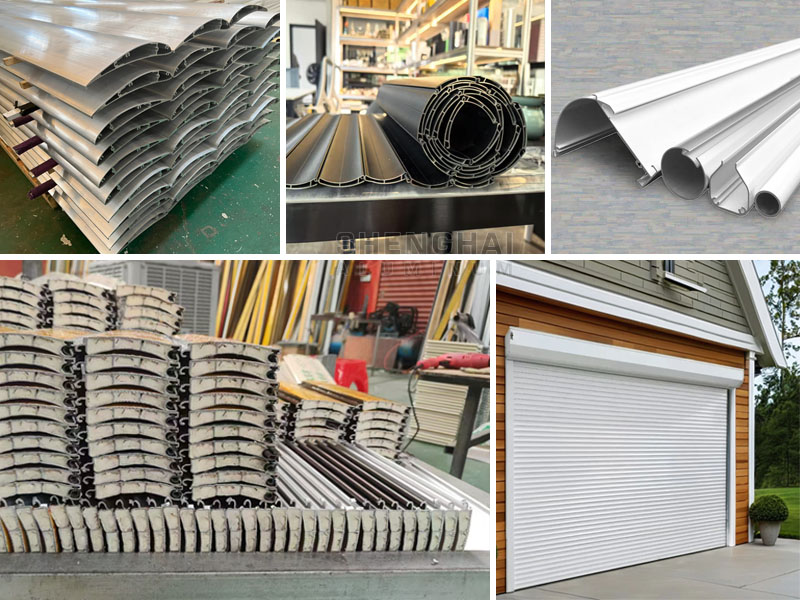

Roller Shutter Profile Production Details

Product Application

Our Factory

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Get a Quote