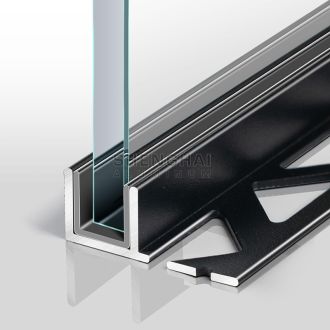

Aluminum Balcony Tile Trim For Outdoor Terrace and Deck

Place of Origin:

Guangdong, China (Mainland)

Grade:

Aluminum Alloy 6000 Series

Temper:

T3-T8

Application:

Decorations

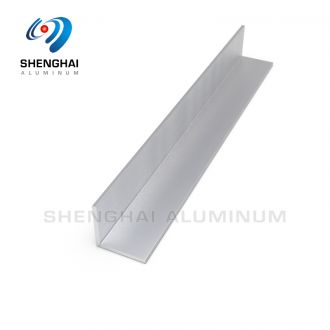

Shape:

Angle

Brand Name:

OEM

Precision:

+-5%

Surface Treatment:

Mill finish, powder coated, anodized, electrophoresis, Polishing

Thickness:

0.6mm-2.0mm

Machining:

High Precision CNC Machining

Deep Process:

Precise cutting, drilling, milling, fabricating

Product Description

We have noticed that balcony tile trim is becoming increasingly popular and is widely used in both commercial and residential buildings, particularly on outdoor terraces and decks. This is because balcony tile trim protects the tiles and prevents rainwater seepage from affecting the downstairs structure. Furthermore, aluminum balcony trim is exceptionally durable, UV-resistant, rust-proof, and aesthetically pleasing, making it a popular choice for many during renovations.Just like our tile balcony trim is made from high-quality 6063 aluminum alloy through extrusion. The extruded profile has a very smooth, texture-free surface. Further surface treatments (anodizing, sandblasting, brushing, electrophoresis, etc.) make the balcony tile trim even more beautiful, corrosion-resistant, rust-resistant, and colorfast, offering high practicality.

Aluminum Trim Features

Specification:

1. Length: 2.44/ 2.5/ 2.7/ 3m or customized

2. Thickness: 0.3mm-3mm or customized

3. Height: 7/ 8/ 8.3 /8.5 mm or customized

4. Colour: Silver/ Gold/ Black/ Wood Grain/ Champagne or customized

5. Type: According to Your Market or Recommend

Punching Hole Shape: Square/ Round/ Triangle/ Star/ Heart/ Diamond/ Letters or customized

Surface Treatment: Polishing, Anodizing oxidation, Powder coating, Electrophoresis

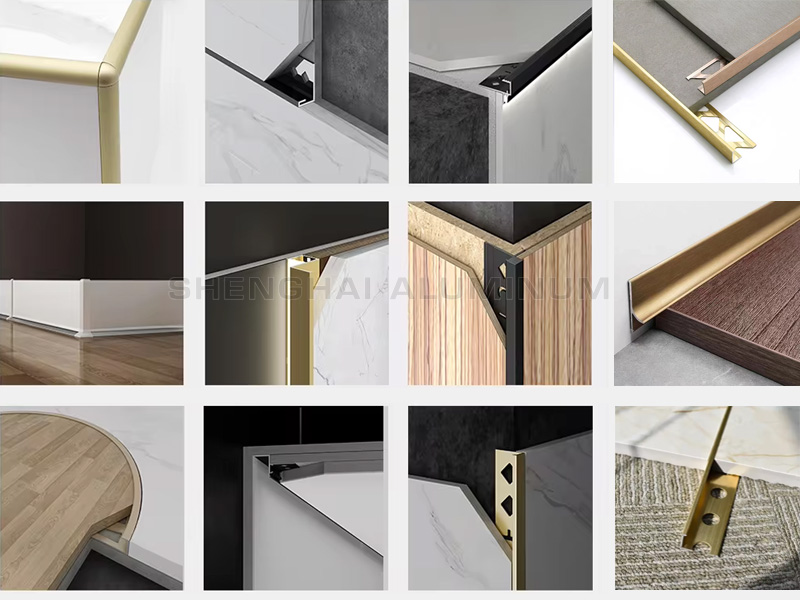

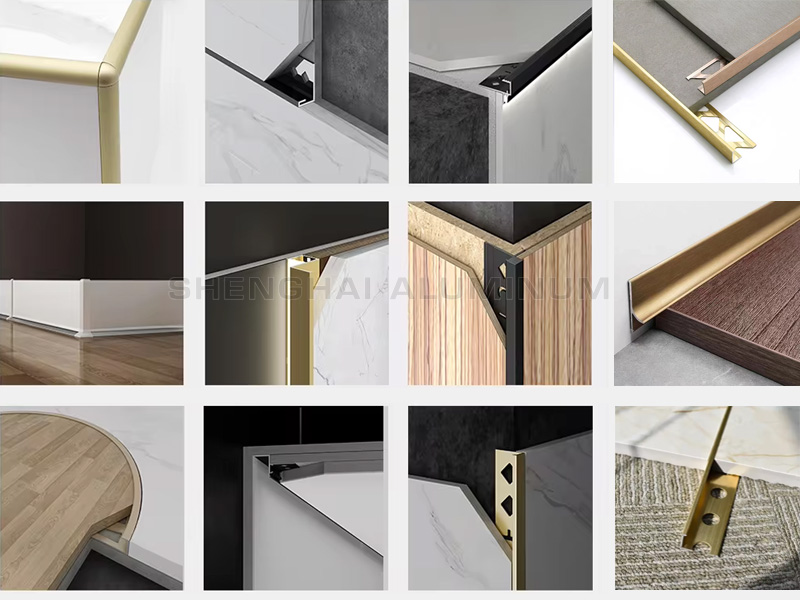

Product Application

Balcony outer or step edge;

Balcony corner or floor edge;

Doorway transition area (between balcony and interior);

Balcony drip edge trim.

Balcony corner or floor edge;

Doorway transition area (between balcony and interior);

Balcony drip edge trim.

Our Factory

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Get a Quote