What Is The Melting Point Of Aluminum Alloy

Updated: 29 Oct 2025

Aluminum alloys are sought after for their corrosion resistance, machinability, and lightweight properties. Among all their features, the melting point of aluminum is especially important for determining its applications in construction, industry, and electronics.

So what is the melting point of aluminum? Aluminum has a melting point of 660.3℃, a key factor enabling its widespread application across many fields. Especially in the manufacturing process, this characteristic enables melting and casting with relatively low energy consumption, further enhancing aluminum's value.

Elements: Commonly used alloying elements, such as copper, magnesium, and zinc, can affect the melting point and other physical properties of aluminum alloys. For example, adding copper can improve the alloy's corrosion resistance and wear resistance, but it will increase the melting point. Adding magnesium, on the other hand, can alter the alloy's structure and hardness, thus lowering the melting point.

Purity: The higher the purity of aluminum, the higher its melting point. This is because high-purity aluminum contains relatively fewer impurities and other elements, naturally resulting in a higher melting point.

Pressure and Temperature: At high temperature and high pressure, the melting point of aluminum alloys increases; under vacuum, it decreases.

Processing Technology: Processes such as annealing, quenching, heat treatment, casting, and extrusion can also affect the melting point of aluminum alloys. This is because these processes alter the structure or shape of the aluminum.

1050: Melting point range 657-660℃

1110: Melting point range 657-660℃

2024: Melting point range 500-635℃

3003: Melting point range 640-655℃

5052: Melting point range 605-650℃

6061: Melting point range 580-650℃

6063: Melting point range 580-650℃

7075: Melting point range 475-635℃

2. Casting: Aluminum alloys have a low melting point and are easily affected by external temperature. The morphology of castings (such as surface finish, shrinkage cavities, and porosity) is also related to the temperature of the aluminum alloy. If the temperature is too high during the melting process, it will lead to a decrease in the surface finish of the casting and an increase in defects such as shrinkage cavities and porosity; if the temperature is too low, it will lead to problems such as voids in the center of the casting and incomplete shapes.

3. Heat Treatment (Quenching, Annealing, Precipitation Hardening) The melting point of aluminum alloys is crucial for hot working and heat treatment processes. During hot working, the melting point determines the processing temperature; excessively high or low temperatures will affect its machinability. During heat treatment, the melting point also determines annealing and quenching temperatures, which directly influence the mechanical properties of the aluminum alloy, including its hardness and toughness.

Transportation: Aluminum's lightweight properties reduce vehicle weight and improve fuel efficiency. Aluminum's lightweight properties are increasingly important in the transportation sector. Whether in automobiles, airplanes, or railways, aluminum can be used to manufacture complex parts, effectively reducing overall weight and improving fuel efficiency and emissions.

Electronics: Aluminum's electrical conductivity helps dissipate heat in electronic products, making it suitable for manufacturing complex components. Aluminum plays a crucial role in the electronics field, often used as a heat sink and casing material. Its excellent electrical conductivity contributes to efficient heat dissipation while providing robust mechanical protection. Furthermore, aluminum's low melting point allows it to be easily cast, meeting the manufacturing requirements for complex electronic components and ensuring the stable and efficient operation of electronic products.

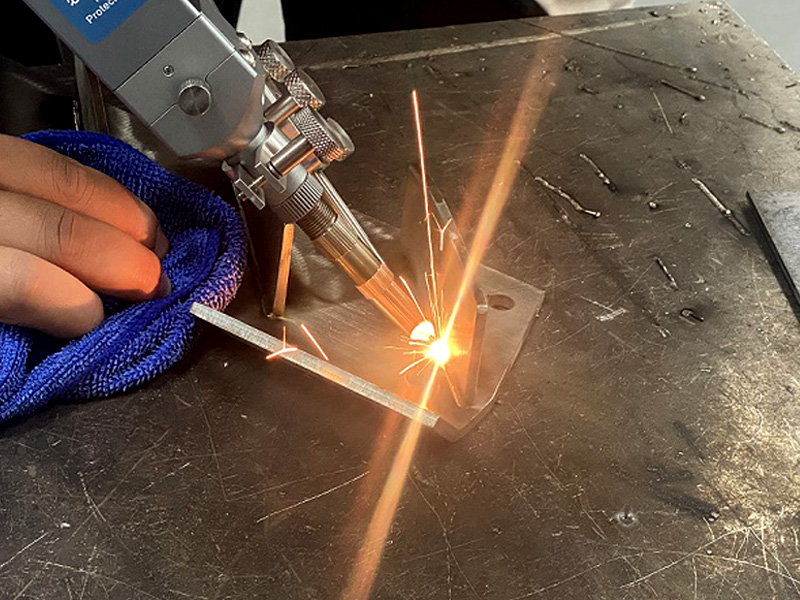

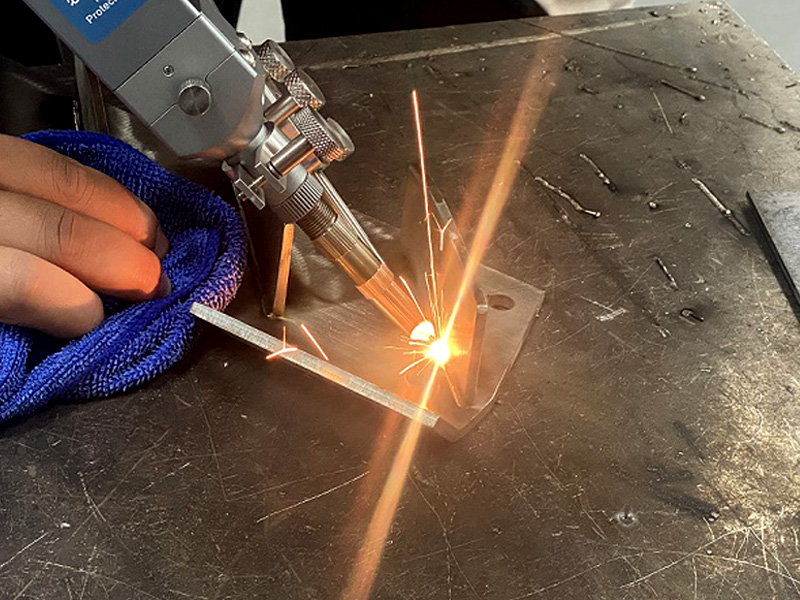

Aluminum's melting point simplifies welding, but temperature control is necessary to prevent performance degradation. Since aluminum can only bond in its molten state, its lower melting point simplifies the welding process. However, in practice, temperature must be carefully controlled to avoid overheating and the resulting reduction in aluminum's properties.

Selection of Welding Materials

The melting point of the welding material must be compatible with that of aluminum to ensure appropriate joint strength. Choosing the right welding material is crucial in aluminum welding. The melting point of the welding material must be compatible with that of aluminum to ensure the metal achieves ideal bonding strength during welding.

Heating aluminum alloys at different temperatures affects their strength, hardness, and machinability. Therefore, understanding the melting point of aluminum allows us to control the temperature during processing to achieve the desired results. Shenghai Aluminum, an integrated manufacturer of aluminum extrusion and deep processing, understands the melting point of aluminum alloys. This knowledge helps prevent uneven wall thickness and ensures a perfect appearance during aluminum extrusion. It also facilitates the fusion of the welding material with the aluminum alloy during welding. In short, knowing the melting point of aluminum is very important for an aluminum extrusion factory.

Heating aluminum alloys at different temperatures affects their strength, hardness, and machinability. Therefore, understanding the melting point of aluminum allows us to control the temperature during processing to achieve the desired results. Shenghai Aluminum, an integrated manufacturer of aluminum extrusion and deep processing, understands the melting point of aluminum alloys. This knowledge helps prevent uneven wall thickness and ensures a perfect appearance during aluminum extrusion. It also facilitates the fusion of the welding material with the aluminum alloy during welding. In short, knowing the melting point of aluminum is very important for an aluminum extrusion factory.

So what is the melting point of aluminum? Aluminum has a melting point of 660.3℃, a key factor enabling its widespread application across many fields. Especially in the manufacturing process, this characteristic enables melting and casting with relatively low energy consumption, further enhancing aluminum's value.

Factors Affecting the Melting Point of Aluminum Alloys

The melting point of aluminum alloys is affected by several factors, primarily including the following:Elements: Commonly used alloying elements, such as copper, magnesium, and zinc, can affect the melting point and other physical properties of aluminum alloys. For example, adding copper can improve the alloy's corrosion resistance and wear resistance, but it will increase the melting point. Adding magnesium, on the other hand, can alter the alloy's structure and hardness, thus lowering the melting point.

Purity: The higher the purity of aluminum, the higher its melting point. This is because high-purity aluminum contains relatively fewer impurities and other elements, naturally resulting in a higher melting point.

Pressure and Temperature: At high temperature and high pressure, the melting point of aluminum alloys increases; under vacuum, it decreases.

Processing Technology: Processes such as annealing, quenching, heat treatment, casting, and extrusion can also affect the melting point of aluminum alloys. This is because these processes alter the structure or shape of the aluminum.

Aluminum Alloy Melting Temperature Range

Different aluminum alloy series have different melting points. We have listed the melting points of these commonly used aluminum alloy grades:1050: Melting point range 657-660℃

1110: Melting point range 657-660℃

2024: Melting point range 500-635℃

3003: Melting point range 640-655℃

5052: Melting point range 605-650℃

6061: Melting point range 580-650℃

6063: Melting point range 580-650℃

7075: Melting point range 475-635℃

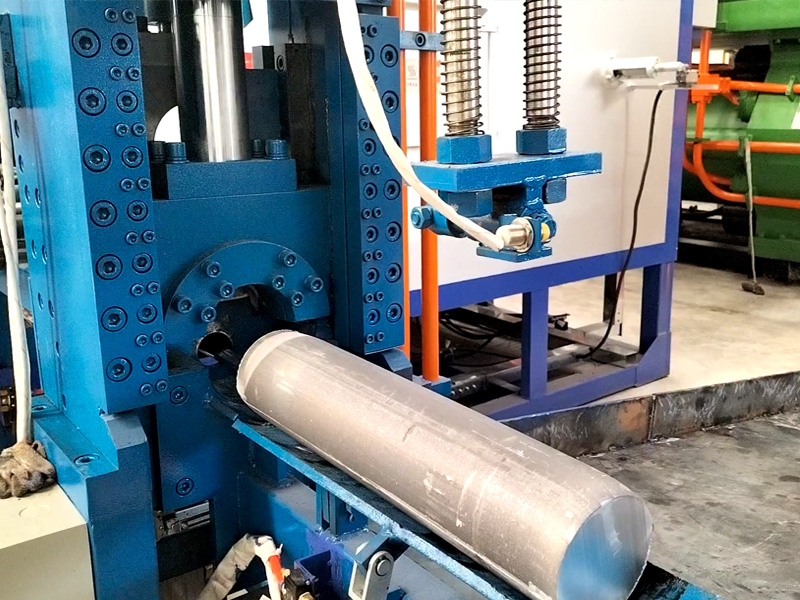

How Does Aluminum Alloy Melting Point Affect Production Processes

1. Extrusion: Aluminum extrusion involves heating an aluminum rod, inserting it into a specific die, and forcing it through to create material with the required cross-sectional profile. If the temperature is below the melting point, the aluminum will lack the necessary plasticity. The press will require higher force, reducing equipment lifespan. Low temperatures also reduce metal fluidity, increasing friction between the aluminum and the die and harming the aluminum's surface quality. Furthermore, inadequate rod temperature and weak alloy fluidity cause inconsistent wall thickness. Therefore, the melting point critically influences extrusion.2. Casting: Aluminum alloys have a low melting point and are easily affected by external temperature. The morphology of castings (such as surface finish, shrinkage cavities, and porosity) is also related to the temperature of the aluminum alloy. If the temperature is too high during the melting process, it will lead to a decrease in the surface finish of the casting and an increase in defects such as shrinkage cavities and porosity; if the temperature is too low, it will lead to problems such as voids in the center of the casting and incomplete shapes.

3. Heat Treatment (Quenching, Annealing, Precipitation Hardening) The melting point of aluminum alloys is crucial for hot working and heat treatment processes. During hot working, the melting point determines the processing temperature; excessively high or low temperatures will affect its machinability. During heat treatment, the melting point also determines annealing and quenching temperatures, which directly influence the mechanical properties of the aluminum alloy, including its hardness and toughness.

The Impact of Aluminum's Melting Point on Applications

Construction Industry: Aluminum's low melting point allows it to be molded into complex shapes, meeting the demands of modern architecture. Aluminum has a wide range of applications in construction, such as building facades, window frames, and roofing materials. Thanks to its low melting point, aluminum can be molded into precise, complex shapes and sizes, thereby meeting the ever-increasing aesthetic and functional requirements of modern architecture.Transportation: Aluminum's lightweight properties reduce vehicle weight and improve fuel efficiency. Aluminum's lightweight properties are increasingly important in the transportation sector. Whether in automobiles, airplanes, or railways, aluminum can be used to manufacture complex parts, effectively reducing overall weight and improving fuel efficiency and emissions.

Electronics: Aluminum's electrical conductivity helps dissipate heat in electronic products, making it suitable for manufacturing complex components. Aluminum plays a crucial role in the electronics field, often used as a heat sink and casing material. Its excellent electrical conductivity contributes to efficient heat dissipation while providing robust mechanical protection. Furthermore, aluminum's low melting point allows it to be easily cast, meeting the manufacturing requirements for complex electronic components and ensuring the stable and efficient operation of electronic products.

Aluminum Melting Point and Welding Process

Welding Process Key PointsAluminum's melting point simplifies welding, but temperature control is necessary to prevent performance degradation. Since aluminum can only bond in its molten state, its lower melting point simplifies the welding process. However, in practice, temperature must be carefully controlled to avoid overheating and the resulting reduction in aluminum's properties.

Selection of Welding Materials

The melting point of the welding material must be compatible with that of aluminum to ensure appropriate joint strength. Choosing the right welding material is crucial in aluminum welding. The melting point of the welding material must be compatible with that of aluminum to ensure the metal achieves ideal bonding strength during welding.