What is 6 Series Aluminium Alloy

Updated: 17 Aug 2021

We know that there are many series of aluminum alloy, but 6 series aluminum alloy is often used. What is 6 series aluminium alloy? What are the features and applications of 6 series?

6 Series Aluminum Alloy Features

The 6 series aluminum alloy is an aluminum alloy with magnesium and silicon as the main alloying elements and the Mg2Si phase as the strengthening phase. The 6 series are heat-treated and strengthenable aluminum alloys. The alloy has the advantages of medium strength, high corrosion resistance, no stress corrosion cracking tendency, good welding performance, the unchanged corrosion performance of the welding zone, good formability and process performance. When the alloy contains copper, the strength of the alloy is close to that of the 2 series aluminum alloy, and the process performance is better than that of the 2 series aluminum alloy. The alloy has good forging performance, but the corrosion resistance becomes worse.

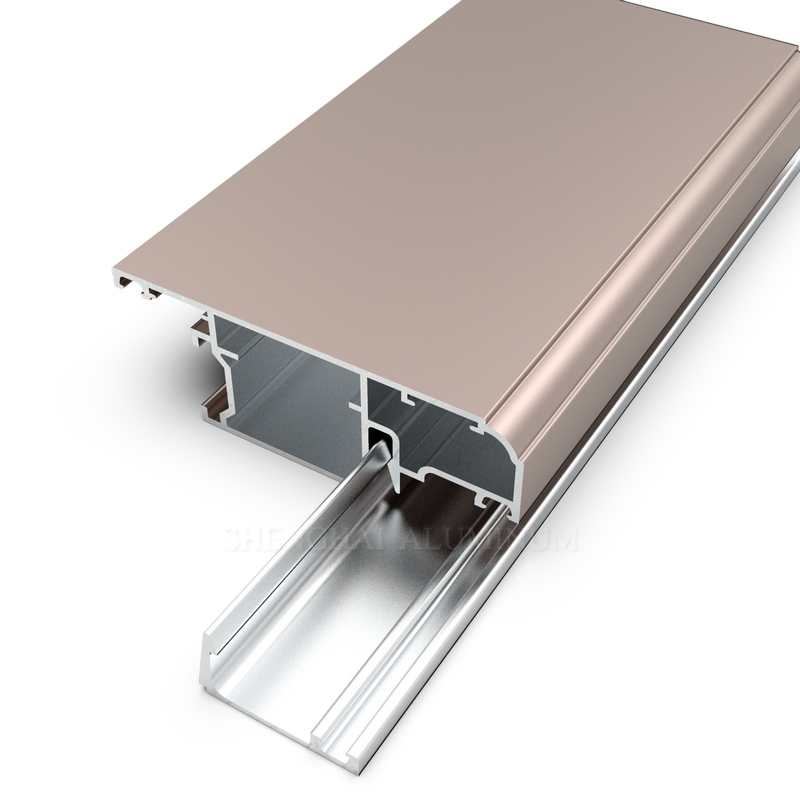

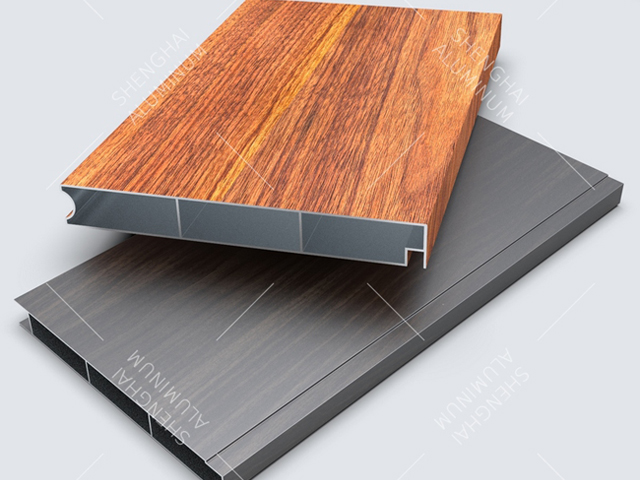

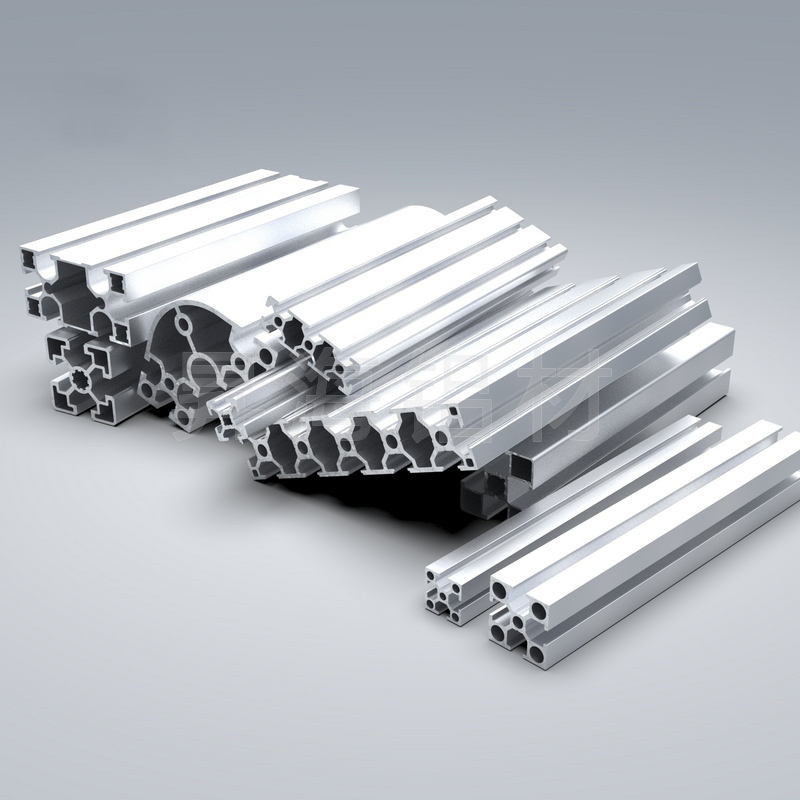

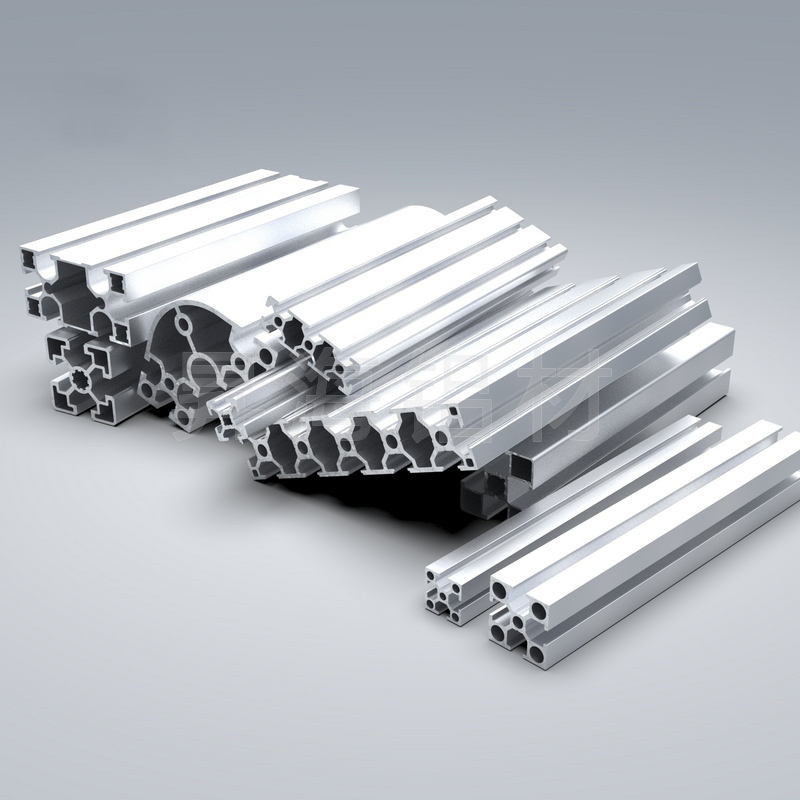

The most widely used 6 series alloys are 6061 and 6063 aluminum alloys. 6061 and 6063 have the best overall performance, and the main products are extruded aluminium profiles. It is the best extrusion alloy. 6061 aluminum and 6063 aluminum alloy are widely used in construction profiles and are the best-extruded alloy materials.

Currently, 6 series aluminum alloy grades are produced: 6005, 6060, 6061, 6063, 6082, 6201, 6262, 6463, 6A02. The applications of the 6 series are listed below in detail.

6 Series Aluminum Alloy Applications

6 Series Aluminum Alloy Applications

6005 extruded profiles and pipes are used for structural parts that require high strength more fabulous than 6063 alloy, such as ladders, TV antennas, etc.;

6009 car body panels;

6010 sheet: car body;

6061 requires a variety of industrial structures with specific strength, weldability and high corrosion resistance, such as pipes, rods, shapes, and Sheet

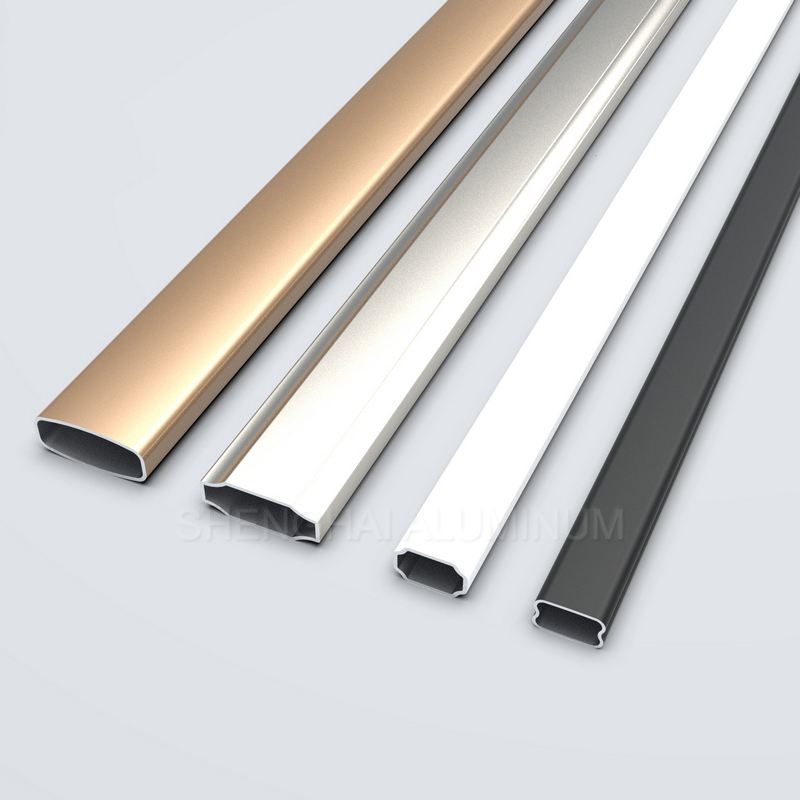

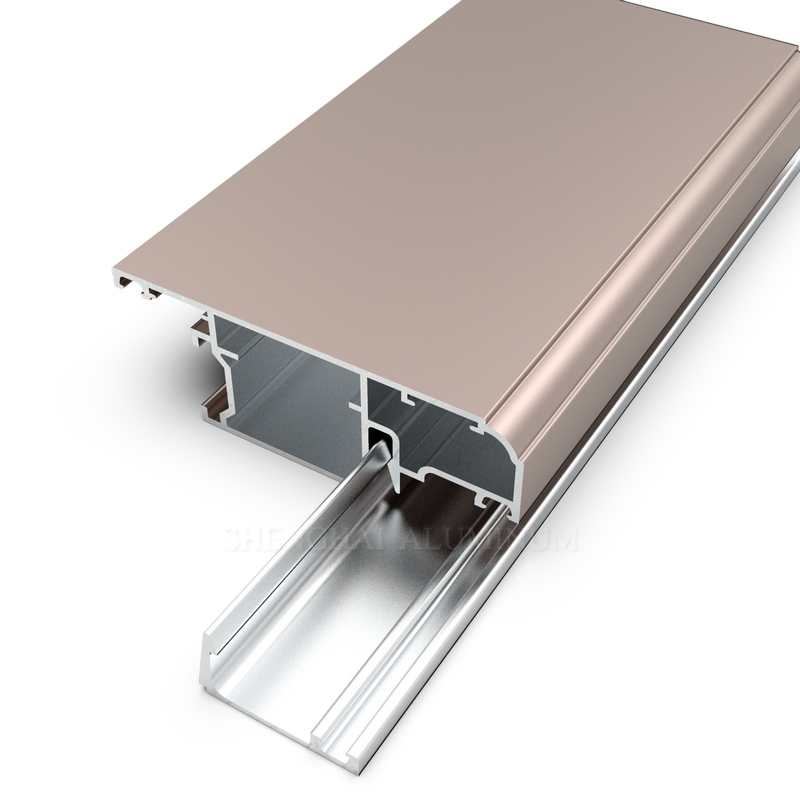

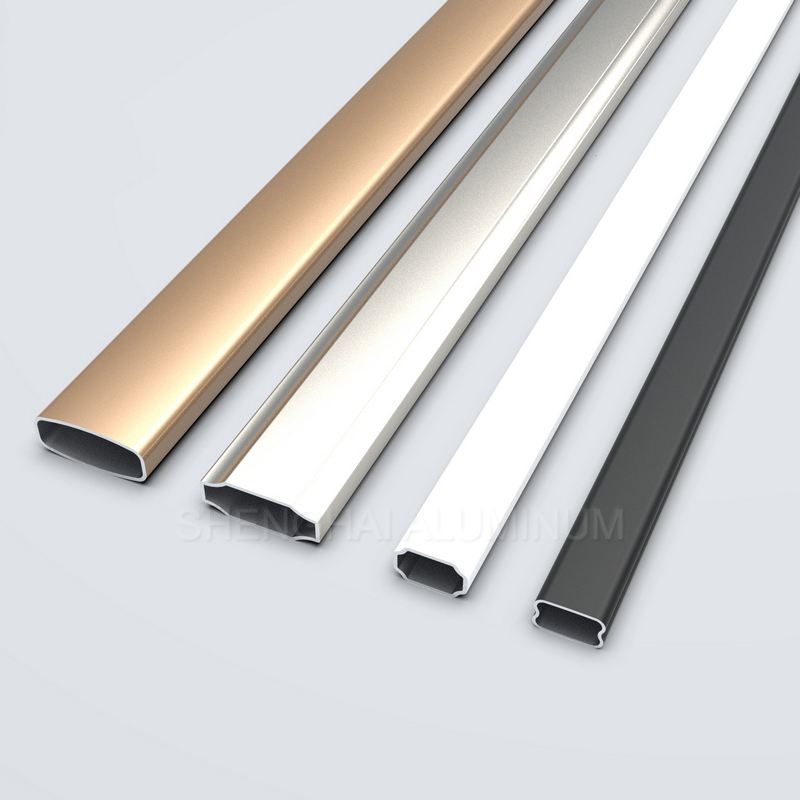

6063 is used in industrial profiles (V-slot, T slotted aluminium extrusion), architectural profiles (door, window, aluminum tile/floor/carpet cover edge trim), irrigation pipes and supplies for vehicles, benches, furniture (cabinet & wardrobe profiles, full aluminum furniture profiles), fences, etc.;

6066 forgings and welding structure extrusion materials;

6070 heavy-duty welded structure and extrusion materials and pipes used in the automotive industry;

6101 High-strength bars, electrical conductors and radiator materials for buses;

6151 is used for die forging crankshaft parts, machine parts and production of rolled rings. It requires not only good forge ability, high strength but also good corrosion resistance;

6201 high-strength conductive rods and wires;

6205 thick plates, pedals and high impact resistant extrusions;

6262 requires threaded high-stress parts with corrosion resistance better than 2011 and 2017 alloys;

Extruded structural parts of 6351 vehicles, pipelines for water, oil, etc.;

6463 Building and various appliance profiles, as well as automotive decorative parts with bright surfaces after anodizing treatment;

6A02 aircraft engine parts, complex forgings and die forgings.

Through the above introduction of the characteristics and applications of 6 series aluminum alloy, we have a clearer understanding of the uses of various specifications of 6 series. If you are looking for 6061 aluminum alloy and 6063 aluminum alloy related products, please feel free to contact us. China Foshan SHENGHAI aluminum extrusion profiles company will provide you with product solutions.

Through the above introduction of the characteristics and applications of 6 series aluminum alloy, we have a clearer understanding of the uses of various specifications of 6 series. If you are looking for 6061 aluminum alloy and 6063 aluminum alloy related products, please feel free to contact us. China Foshan SHENGHAI aluminum extrusion profiles company will provide you with product solutions.

6 Series Aluminum Alloy Features

The 6 series aluminum alloy is an aluminum alloy with magnesium and silicon as the main alloying elements and the Mg2Si phase as the strengthening phase. The 6 series are heat-treated and strengthenable aluminum alloys. The alloy has the advantages of medium strength, high corrosion resistance, no stress corrosion cracking tendency, good welding performance, the unchanged corrosion performance of the welding zone, good formability and process performance. When the alloy contains copper, the strength of the alloy is close to that of the 2 series aluminum alloy, and the process performance is better than that of the 2 series aluminum alloy. The alloy has good forging performance, but the corrosion resistance becomes worse.

The most widely used 6 series alloys are 6061 and 6063 aluminum alloys. 6061 and 6063 have the best overall performance, and the main products are extruded aluminium profiles. It is the best extrusion alloy. 6061 aluminum and 6063 aluminum alloy are widely used in construction profiles and are the best-extruded alloy materials.

Currently, 6 series aluminum alloy grades are produced: 6005, 6060, 6061, 6063, 6082, 6201, 6262, 6463, 6A02. The applications of the 6 series are listed below in detail.

6005 extruded profiles and pipes are used for structural parts that require high strength more fabulous than 6063 alloy, such as ladders, TV antennas, etc.;

6009 car body panels;

6010 sheet: car body;

6061 requires a variety of industrial structures with specific strength, weldability and high corrosion resistance, such as pipes, rods, shapes, and Sheet

6063 is used in industrial profiles (V-slot, T slotted aluminium extrusion), architectural profiles (door, window, aluminum tile/floor/carpet cover edge trim), irrigation pipes and supplies for vehicles, benches, furniture (cabinet & wardrobe profiles, full aluminum furniture profiles), fences, etc.;

6066 forgings and welding structure extrusion materials;

6070 heavy-duty welded structure and extrusion materials and pipes used in the automotive industry;

6101 High-strength bars, electrical conductors and radiator materials for buses;

6151 is used for die forging crankshaft parts, machine parts and production of rolled rings. It requires not only good forge ability, high strength but also good corrosion resistance;

6201 high-strength conductive rods and wires;

6205 thick plates, pedals and high impact resistant extrusions;

6262 requires threaded high-stress parts with corrosion resistance better than 2011 and 2017 alloys;

Extruded structural parts of 6351 vehicles, pipelines for water, oil, etc.;

6463 Building and various appliance profiles, as well as automotive decorative parts with bright surfaces after anodizing treatment;

6A02 aircraft engine parts, complex forgings and die forgings.