Surface Treatment of Aluminum Profiles - Anodizing

Updated: 8 Feb 2023

What is surface treatment of aluminum profile

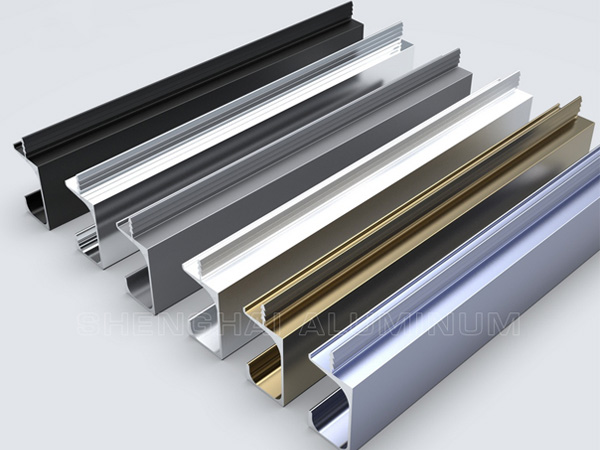

Surface treatment: A protective layer can be formed on the product's surface to protect the aluminum profile after treatment by mechanical and chemical methods. It can achieve a stable state in nature, increase the profile's corrosion resistance and increase its beauty.The surface treatment of aluminum profiles is generally completed by mechanical processing, chemical and physical. Standard extruded aluminum surface treatment includes anodizing, sandblasting, high-gloss, powder coating, electroplating, electrophoresis and other processes.

Since anodizing is a frequently used surface treatment for aluminum profiles, the anodizing process is introduced in detail today.

Anodized aluminum profile

Anodizing can make the surface of aluminum profiles form a uniform and dense oxide film (Al2O3. 6H2O). This film can make the surface hardness of the profile reach (200-300HV). If special products can be hard anodized, the surface hardness of the product can reach 400-1200 HV. Therefore, hard anodizing is an indispensable surface treatment process for cylinders and transmission devices. In addition, the wear resistance of this product is very good, so it can be used for aviation and aerospace related products.

Difference between anodizing and hard anodizing: Anodizing can be colored and has better decoration than hard anodizing.

Construction points: Anodizing is very strict on material requirements. Different materials have different decorative effects on the surface. Commonly used materials are aluminum alloy 6061, 6063, 7075, and 2024. Among them, 2024 is less effective. Due to the different content of CU in the material, 7075 hard anodizing is yellow, and 6061 and 6063 are brown. But ordinary anodized 6061, 6063, and 7075 are not much different, but 2024 easily appears with many gold spots.

Common anodizing processes are brushed matte natural color, brushed glossy natural color, and brushed matte (can be dyed to any color). Polished glossy natural color, polished matte natural color, polished glossy dyeing, polished matte dyeing. Spray noisy bright surface natural color, spray noisy matte surface natural color, sand spray dyeing. All the above plating can be used on lighting equipment.

Anodizing process flow

Oil Removal->Alkali Etching->Chemical Throwing->Neutralization->Lidi->Neutralization

Anodizing->Dyeing->Sealing->Hot water washing->Drying

1. Mottled appear on the surface. This abnormality is generally caused by poor metal tempering or the material itself being too bad. Treatment, re-heat treatment, or replace the material.

2. Rainbow color appears on the surface. An anode operation error generally causes this abnormality. Loose when hanging, resulting in poor product conductivity. Treatment, anodized.

3. Serious surface scratches. This abnormality is generally due to the transportation or processing process. Treatment, de-energized, polished and re-energized.

4. White spots appear on the surface when dyeing. This abnormality is usually due to oil or other impurities in the water when the anode is working.

Quality standard

1. film thickness 5-25um, hardness above 200HV, seal hole test color change rate less than 5%

2. Salt spray test above 36 hours and can reach the CNS standard above 9 levels.

3. no bruises, scratches, color clouds, etc., on the appearance. The surface can not have a hanging point, yellowing and other undesirable phenomena.

Die-casting aluminum, such as A380, A365, A382, etc. can not do anodizing

Shenghai Aluminum is a manufacturer of extruded and deep processing aluminum profiles. If your project needs aluminum profiles, please contact us today.