How To Customize Your Aluminum Enclosures

Updated: 14 Mar 2023

What is aluminum profile enclosure

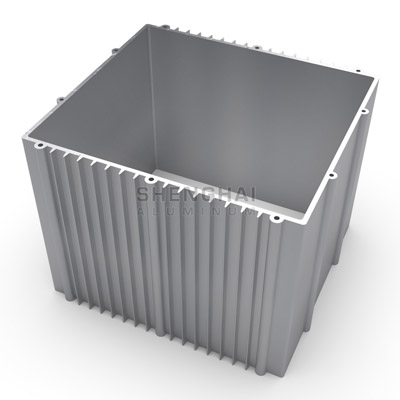

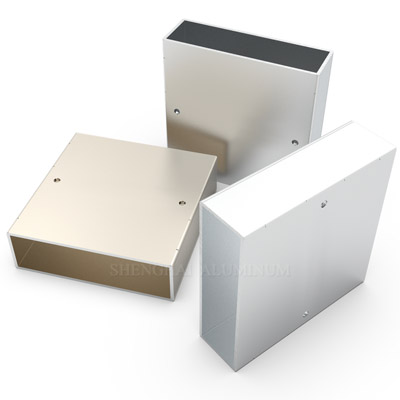

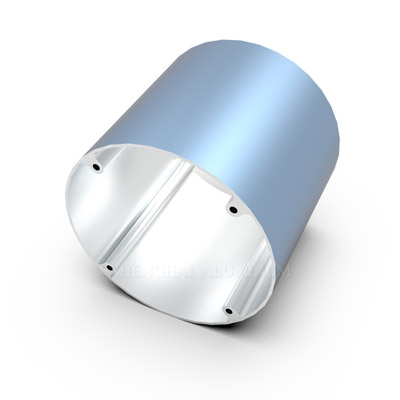

Aluminum enclosures are commonly used in electronics such as for housing circuit boards, power supplies, and other electronic components. Extruded aluminum box to protect and house electronic components. They are lightweight, durable, and have excellent heat dissipation properties.Aluminum extrusions are a popular choice for enclosures due to their versatility, strength, and ease of customization.

Customized aluminum profile enclosures must consider multiple factors, including design requirements, aluminum profile selection, processing methods, surface treatment, etc. We are a manufacturer of aluminum enclosures and can provide a one-stop service.

What to pay attention to when choosing aluminum extrusion for enclosure

Strength: Aluminum profiles must have sufficient strength to resist external pressure and extrusion and protect internal equipment and components.Heat dissipation: The aluminum profile section should have good heat dissipation performance to prevent equipment from overheating, so the cross-sectional shape needs to have appropriate heat dissipation channels or fins.

Electromagnetic shielding: Aluminium extruded sections need to provide good electromagnetic shielding performance to protect internal components from external electromagnetic interference, so the cross-sectional shape needs to have an appropriate electromagnetic shielding structure.

Installation: Aluminum extrusion profiles need to be easy to install, so the cross-sectional shape needs to have a certain connection structure, such as plug sockets, corner connectors, etc.

Appearance: As an external decorative part, aluminum profiles must also have a good appearance and aesthetics.

Surface Processing of Aluminum Profile Enclosure

1. PolishingUse mechanical, chemical or electrochemical methods to reduce the roughness of the surface of the aluminum profile enclosure to obtain a bright and smooth surface. Polishing technology is mainly divided into mechanical, chemical, and electrolytic polishing. After mechanical and electrolytic polishing, the aluminum parts of the car can be close to the mirror effect of stainless steel. This kind of aluminum profile shell gives people a sense of high-end, simple and fashionable in the future.

2. Sandblasting

Cleaning and roughening metal surfaces by the impact of high-velocity sand streams. Surface treatment of the aluminum profile shell by this method can obtain a certain degree of cleanliness and different roughness on the surface of the aluminum profile housing, improve the mechanical properties of the workpiece surface, thereby improving the fatigue resistance of the workpiece, and increasing the distance between the workpiece and the coating. It can improve the adhesion between the coatings, prolong the durability of the coating film, and is also conducive to the smoothness and decoration of the coating. We often see this kind of aluminum enclosure processing technology in the solar frame, and it is also increasingly used by the existing TV shell or middle frame.

3. Wire drawing

Metal wire drawing is the process of repeatedly scraping outlines with sandpaper. Drawing can be divided into straight, random, spiral, and thread. The metal wire drawing process can clearly show every tiny line mark so that the metal matte shines with a delicate hair luster and the extruded aluminium enclosure integrates fashion and technology.

4. Strong light cutting

The finishing machine strengthens the diamond knife to cut the parts on the spinning machine spindle rotating at high speed (usually 20000 rpm) to form a local high-gloss area on the surface of the extruded aluminum box. The brightness of the cutting highlights is affected by the speed of the milling cutter. The faster the drill speed, the brighter the cutting highlights. Conversely, the darker the cutting highlights, the easier it is to produce the pattern. High-gloss cut aluminum profiles are often used in mobile phones. In recent years, some high-end TV metal frames have adopted high-gloss milling technology, coupled with anodizing and wire-drawing technology, making the TV full of fashion and technology.

5. Anodizing

Anodization refers to the electrochemical oxidation of metals or alloys. Under the corresponding electrolyte and specific process conditions, aluminum and its alloys form an oxide film on the aluminum product (anode) under the action of an applied current. Anodizing can not only solve the defects of aluminum surface hardness and wear resistance but also prolong the service life of aluminum and enhance its beauty of aluminum. It has become an indispensable part of aluminum surface treatment and is currently the most widely used and successful waterproof aluminum enclosure processing craft.

6. Two-color anodizing

Two-color anodizing refers to anodizing the aluminum profile shell and giving different colors to specific areas. The two-color anodizing process is complicated and the cost is high. However, comparing the two colors can better reflect the high-end and unique appearance of the aluminium profile enclosure.

Application of aluminum profile enclosure

1. Electronic productsCharging treasure enclosure, circuit board shell, chassis shell.

2. Electromechanical housing

Servo motor casing, cylinder, etc.

3. Power shell

Mobile power shell, power box shell.

4. Lamp housing

Lamp housings are mainly LED lamp housings, explosion-proof lamp housings, and led display housings.

5. Controller shell

Solar lamp controller shell, inverter shell.

6. Meter housing

Such as power meter housing, security instrument casing, detector case.

In modern society, aluminum extrusion enclosure is no longer just simple casing, and more users and OEM manufacturers are pursuing higher quality and more innovative shapes. They want the aluminum profile enclosure manufacturer to provide better quality and a unique appearance so that their products can stand out in the market and show higher quality. We aim to provide high-quality and customized enclosure aluminum profiles for enclosure factories.