How to Choose Industrial Aluminium Profile Model

Updated: 12 Apr 2021

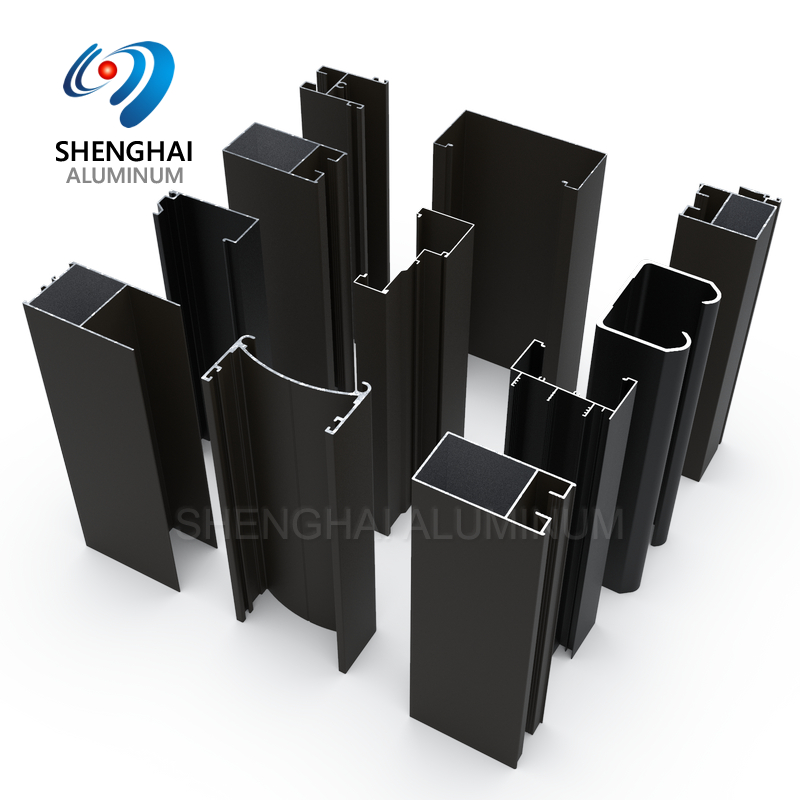

We know that there are many specifications and models of industrial aluminium profile (commonly used 6063-T5 / 6061-T6), how to choose the appropriate specifications and models? The following Shenghai Aluminum introduces several selection methods, which can be used as a reference for the selection of industrial aluminum profiles.

1. Load-bearing & strength

Different profile specifications represent different load-bearing requirements, and suitable profile specifications can be selected according to specific load-bearing requirements. Strength is an important indicator to measure the carrying capacity of industrial aluminum profiles. You can give the required industrial aluminum profile model according to your product needs and the corresponding load-bearing capacity. Aluminum Profiles Manufacturer will calculate the deformation of this type of industrial aluminum profile under static load and no load according to the calculation formula of aluminum profile deformation. Including the maximum allowable bending stress of industrial aluminum profiles. Deformation is an important basis for selection. Determine whether the industrial aluminum profile of this model can meet the load-bearing capacity required by the customer according to the range value of the deformation. If it cannot be achieved, a profile with a larger load-bearing capacity should be selected. Or by changing the frame structure to increase the load-bearing capacity. The unit mass and moment of inertia of different types of industrial aluminum profiles are different, so the carrying capacity will be different.

Each profile has its own purpose and scope of use. We need to find a profile suitable for ourselves according to our needs, instead of blindly pursuing the strength of the aluminum profile.

2. Application environment

Aluminum Extrude Profiles application environment is an important basis for selecting models. If the application environment requires the industry aluminum profile to have corrosion resistance, you can choose the corrosion-resistant model (1 series has the best corrosion resistance, 5 series has excellent corrosion resistance, 3 series & 6 series have general corrosion resistance, 2 series & 7 series are resistant Corrosion is weak). If it is a high temperature and corrosive production workshop, the 6063-T5 industrial aluminum profile is the most durable. If it is a production workshop at room temperature and relatively good production conditions, general industrial aluminum profile can be used that do not require much corrosion resistance. Aluminum profile.

3. Appearance requirements

4. Processability

Machining performance includes insert forming performance and cutting performance. Because formability is related to state, after selecting aluminum alloy grades, the strength range of various states must be considered. Generally, high-strength materials are not easy to form. Taiguo needs to bend, stretch, and deep-draw the aluminum material. The formability of the material in the annealed state is the best. On the contrary, the formability of the material in the heat-treated state is the worst. Aluminum alloy has poor machinability and better machinability for molds and mechanical parts. On the contrary, low-strength ones have poor machinability. For products that require cutting, such as molds and mechanical parts, the machinability of aluminum alloy is important. Consider factors.

Through the selection method introduced above, if you don't know how to choose the industrial aluminum profile model, you can give it to the technical staff of aluminium profile manufacturer to help you make the selection.

Industrial aluminum profiles are already a mature product of Foshan Shenghai Aluminum. With the development of the company, assembly line conveying equipment and industrial framework are the essence of R&D and manufacturing, and incorporate the characteristic technologies of other countries. With rich R&D and production experience, familiar with domestic and foreign market needs, personalized products and profiled products that can meet the special requirements of customers.