How to Choose Aluminum LED Strip Extrusion Channel

Updated: 28 Feb 2023

What is LED strip aluminum extrusion channel

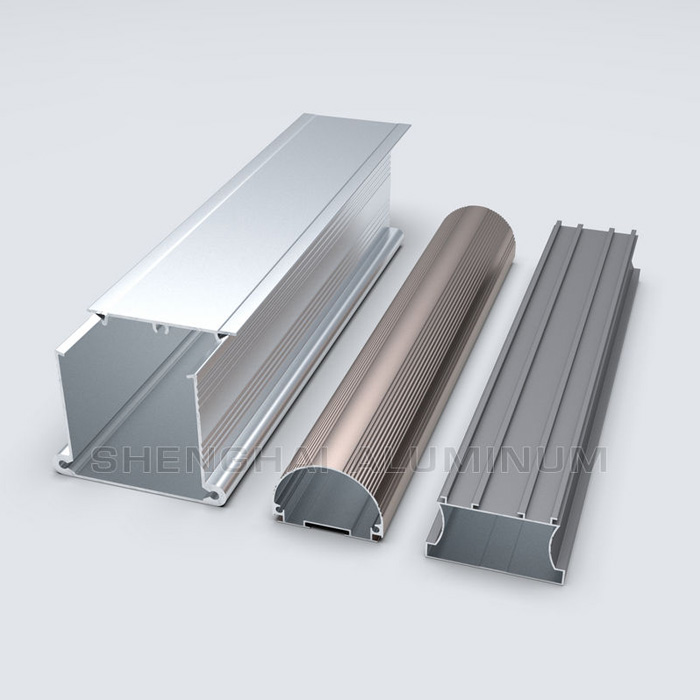

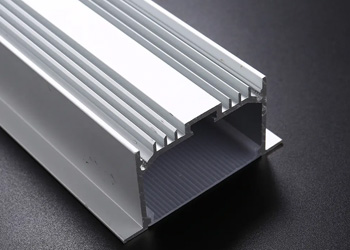

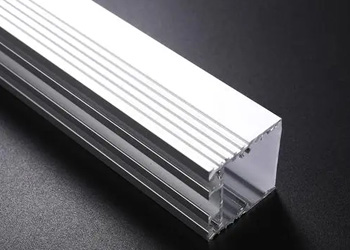

Aluminum LED extrusion channel, also known as an LED aluminum profile or LED strip channel, is a specially designed aluminum extrusion that houses LED light strips. The extrusion channels are used to protect and diffuse the light from the flexible LED strips while also providing a sleek and professional look for installations.LED aluminum profiles come in many shapes and sizes, including rectangular, circular, and triangular shapes. They also have different surface finishes, such as frosted or clear covers, to diffuse or direct the light as needed. Some extrusion channels may also have additional features, such as mounting brackets, end caps, or lenses.

Using a flexible LED profile provides several benefits, including improved thermal management, protection for the LED strip, and a more aesthetically pleasing appearance. The aluminum construction of the extrusion profile helps dissipate heat generated by the LEDs, which can extend the life of the LEDs and prevent overheating. The channels also protect the LED strip from dust, moisture, and other elements that can damage the LEDs over time. Finally, the extrusion channels give LED installations a polished and professional appearance, which can be particularly useful in commercial or residential settings.

How to choose right extrusion channel for LED strip

As an expert in aluminum profiles, Shenghai Aluminum can provide the following suggestions for LED lighting suppliers to help them choose high-quality extrusion profiles to support their LED strip lighting systems.1. Shape

According to different usage scenarios, choosing the appropriate shape of the aluminum profile is necessary.

Several common shapes include right-angle, circular, triangular, track and recessed.

The right-angle type is the most common type, generally used for installation on the wall or ceiling, and the internal structure can be U-shaped or V-shaped, used to fix and protect the LED tape and at the same time realize the heat dissipation and cooling of the LED strip through a special design beautiful.

The circular type is used for the installation of the ring light strip. The internal structure can be semicircular or circular. Different installation and connection methods can be realized through different end caps and accessories.

The triangle type is used to connect LED light strips in different directions. The internal structure can be V-shaped or triangular, which can realize the connection and fixing of multiple LED tapes and different installation and connection methods through different accessories.

The track type is generally used in scenes that need to adjust the light strips' direction or move the light bar's position. The movement and adjustment of the LED light strip are realized through the design of the track and slider.

The embedded type is used in scenes that need to be embedded in the wall or ceiling. Through special design and accessories, the connection and fixing of the aluminum profile and the wall or ceiling can be realized, and the safety and beauty of the LED tape can be guaranteed.

Choosing the right shape is one of the important factors in choosing the right extrusion channel for your LED strip.

Selecting the appropriate aluminum profile size for LED strip needs to consider factors such as the width and thickness of the LED light strip, the thermal conductivity of the extruded aluminum, the installation environment and requirements, and the strength and stability of the aluminum profile. Choosing an aluminum profile with the same or slightly larger width than the LED light tape is generally recommended, and choosing the appropriate model and size according to the actual situation. If you are still determining, consult the Shenghai Aluminum extrusion profile manufacturer for professional advice. High-quality aluminum profiles can effectively guarantee the long-term stable operation and good heat dissipation effect of the LED light strip system.

3. Color (extrusion profile surface treatment )

LED strip aluminum channels usually have different surface treatment methods, such as mill finish, anodizing, electrophoretic coating, powder coating, and water transfer printing. When choosing the surface treatment method for aluminum profiles, specific application scenarios and requirements need to be considered. For example, if you need to improve the corrosion resistance and wear resistance of aluminum mounting channel, you can choose treatment methods such as oxidation or electrophoretic coating; if you need to increase the decorative effect, you can choose treatment methods such as spraying or water transfer printing.

When choosing the surface treatment method for the aluminum profile, it is also necessary to consider the influence of the treatment method on the performance of the aluminum profile itself. For example, some surface treatment methods may impact the thermal conductivity of extrusion profiles, so they need to be selected for specific situations.

Choosing the right surface treatment method can add different characteristics and decorative effects to aluminum profiles and meet different application requirements.

We hope to provide more useful information to help you make better decisions. If you have any questions or need further assistance, please do not hesitate to contact us. Our team is always ready to provide professional advice and support so that you can be more confident and satisfied when choosing extrusion profiles for LED strips. Thank you for your attention, and look forward to cooperating with you!