Can Extruded Aluminum Be Welded

Updated: 30 Sep 2025

Many people often ask if extruded aluminum can be welded. Indeed, it can. However, welding performance varies depending on the grade of aluminum alloy. Therefore, when welding aluminum extrusions, consider the alloy grade, wall thickness, and application scenario to ensure your aluminum extrusion welding needs are met.

1. 5000 Series Aluminum Alloys: Primarily composed of magnesium as the primary alloying element, they offer excellent corrosion resistance, processability, and weldability. Common weldable 5000 series aluminum alloys include 5052 and 5083. These alloys maintain excellent strength and ductility during welding and are suitable for a variety of engineering structures requiring welding.

2. 6000 Series Aluminum Alloys: With magnesium and silicon as primary alloying elements, these alloys offer high strength and excellent workability. 6061 and 6063 are two commonly weldable aluminum alloys in the 6000 series. They maintain stable properties during welding and produce high-strength welded joints, making them suitable for engineering structures subject to heavy loads. They are commonly used in buildings, doors, windows, and structural components.

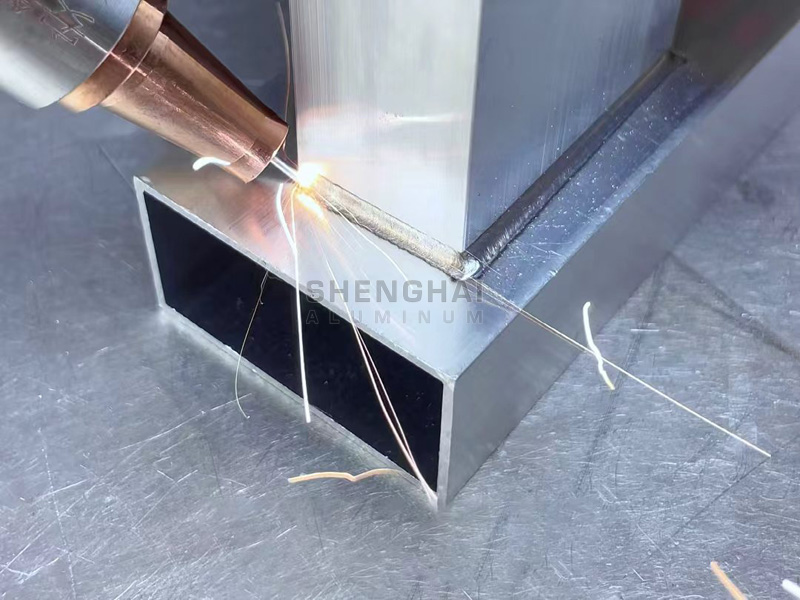

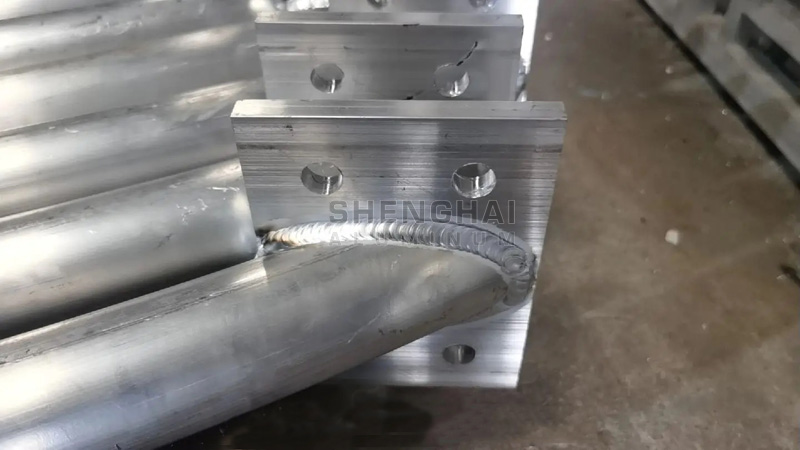

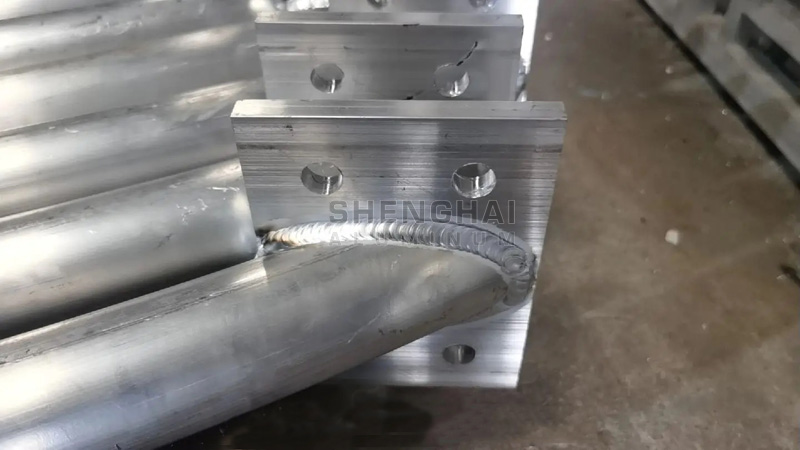

Shielded inert gas welding (TIG or MIG) is often used for welding aluminum extrusions.

TIG welding (argon arc welding)

TIG welding is a common method for welding aluminum alloys. It uses an inert gas as a shielding gas, produces minimal spatter and contamination, and can weld thin sheets, special-shaped materials, and high-strength materials. However, it requires advanced operator skills and manual adjustment of welding parameters.

MIG Welding (Gas Metal Arc Welding)

MIG welding uses an inert gas shield and is suitable for lightweight structural parts, thin plates, and simpler profiles. It offers high speed and high efficiency, and can be automated; however, it requires more complex equipment to control the gas flow and power supply.

Resistance Welding

Resistance welding uses the resistance of an electric current passing through aluminum sheets to generate heat, forming a weld between two sheets. It is suitable for thickened components and applications where minimal distortion is required. However, resistance welding can produce scale, which requires protective treatment and treatment.

Laser Welding

Laser welding uses a high-energy laser beam for welding, offering advantages such as high precision, high quality, and smooth weld surfaces. It is suitable for precision welding of aluminum alloys, but requires expensive equipment and enhanced safety measures.

The above are common welding methods for aluminum profiles. Choosing the appropriate method requires consideration of factors such as the material type, thickness, shape, and intended use. It is also important to use standard welding equipment, shielding gas, and welding materials.

1. Cleaning

When cleaning aluminum and aluminum alloys, the weld joint and the welding wire surface must be thoroughly cleaned of oxide films and oil stains before welding.

Chemical Cleaning

Chemical cleaning is highly efficient and provides consistent quality, making it suitable for cleaning welding wire and smaller, batch-produced workpieces. Both immersion and scrubbing methods can be used. Surface degreasing can be achieved with organic solvents such as acetone, gasoline, and kerosene. Alkaline cleaning with a 5% to 10% NaOH solution at 40°C to 70°C for 3 to 7 minutes (for pure aluminum, the time may be slightly longer, but no more than 20 minutes), followed by rinsing with running water. Followed by an acid clean with a 30% HNO₃ solution at room temperature to 60°C for 1 to 3 minutes, followed by rinsing with running water, and air drying or low-temperature drying.

Mechanical Cleaning

Mechanical cleaning is often used for larger workpieces, longer production cycles, or when contamination persists after multiple welding cycles or chemical cleaning. First, wipe the surface with an organic solvent, such as acetone or gasoline, to remove any oil. Then, directly brush with a copper or stainless steel wire brush (0.15 mm to 0.2 mm in diameter) until the metallic luster is revealed. Grinding with a grinding wheel or ordinary sandpaper is generally not recommended to prevent sand particles from remaining on the metal surface and entering the molten pool during welding, causing defects such as slag inclusions. Alternatively, a scraper or file can be used to clean the surface to be welded.

After cleaning: If the material has been stored for an extended period (e.g., over 24 hours), it should be reprocessed.

2. Backing Plate

Aluminum alloys have very low strength at high temperatures, and liquid aluminum has good fluidity, making weld metal prone to collapse during welding. To ensure full penetration without collapse, a backing plate is often used to support the molten pool and surrounding metal. Backing plates can be made of graphite, stainless steel, carbon steel, copper, or copper rod. A circular groove is cut into the backing plate's surface to ensure the weld's reverse side is formed. Single-sided welding and double-sided forming are also possible without a backing plate, but this requires skilled welding skills or the use of advanced process measures such as strict automatic feedback control of arc energy.

3. Preheating Before Welding

Thin and small aluminum parts generally do not require preheating. Preheating is acceptable for parts with a thickness of 10 mm to 15 mm. Depending on the type of aluminum alloy, the preheating temperature can range from 100°C to 200°C. Heating can be done with an oxyacetylene flame, electric furnace, or blowtorch. Preheating can minimize deformation and defects such as porosity in the weld.

Post-weld Treatment

1. Residual flux and slag left in and around the weld seam after welding can damage the passivation film on the aluminum surface and sometimes corrode the aluminum part. They should be cleaned. Simple workpieces with general requirements can be cleaned with simple methods such as hot water flushing or steam blasting. For aluminum parts with complex shapes and high requirements, scrub them in hot water with a stiff brush, then immerse them in a 2% to 3% aqueous chromic anhydride or potassium dichromate solution at approximately 60°C to 80°C for 5 to 10 minutes. Rinse with a stiff brush, rinse in hot water, and dry in an oven, hot air, or naturally.

2. Post-weld heat treatment: Aluminum containers generally do not require heat treatment after welding.

If welding is not an option, what are some alternatives?

With advances in production technology, many aluminum profiles can now be assembled and used without requiring welding. The following are some common alternatives to welding for aluminum:

Mechanical connections (angle brackets, screws, rivets) → High strength and removable;

Gluing/structural adhesives → Aesthetically pleasing and airtight;

Plug-in/clip-on connections → Quick assembly, suitable for furniture and display structures.

In the window, door, and curtain wall industries, the most commonly used method is angle brackets combined with structural adhesives, which have virtually replaced welding.

Generally, the decision to weld aluminum extrusions depends on the profile, application scenario, and specific needs. Our aluminum extrusion manufacturers typically support welding, bending, cutting, and other processing techniques, primarily based on customer needs and our own production experience. If you're interested in understanding other advanced processing techniques beyond aluminum extrusion welding, please contact us for a technical guide to advanced processing techniques.

Which aluminum extrusions are suitable for welding

Weldable aluminum extrusions are typically 5000 and 6000 series aluminum alloys. These alloys are widely used for their excellent weldability and mechanical properties. 6061 and 6063 are particularly popular. The extrusion process allows for complex cross-sections, and their magnesium and silicon content ensures they maintain excellent strength and corrosion resistance after welding.1. 5000 Series Aluminum Alloys: Primarily composed of magnesium as the primary alloying element, they offer excellent corrosion resistance, processability, and weldability. Common weldable 5000 series aluminum alloys include 5052 and 5083. These alloys maintain excellent strength and ductility during welding and are suitable for a variety of engineering structures requiring welding.

2. 6000 Series Aluminum Alloys: With magnesium and silicon as primary alloying elements, these alloys offer high strength and excellent workability. 6061 and 6063 are two commonly weldable aluminum alloys in the 6000 series. They maintain stable properties during welding and produce high-strength welded joints, making them suitable for engineering structures subject to heavy loads. They are commonly used in buildings, doors, windows, and structural components.

Common Welding Methods for Aluminum Extrusions

Almost all welding methods can be used to weld aluminum and aluminum alloys; however, the adaptability of aluminum and aluminum alloys to various welding methods varies, and each welding method has its own specific applications.Shielded inert gas welding (TIG or MIG) is often used for welding aluminum extrusions.

TIG welding (argon arc welding)

TIG welding is a common method for welding aluminum alloys. It uses an inert gas as a shielding gas, produces minimal spatter and contamination, and can weld thin sheets, special-shaped materials, and high-strength materials. However, it requires advanced operator skills and manual adjustment of welding parameters.

MIG Welding (Gas Metal Arc Welding)

MIG welding uses an inert gas shield and is suitable for lightweight structural parts, thin plates, and simpler profiles. It offers high speed and high efficiency, and can be automated; however, it requires more complex equipment to control the gas flow and power supply.

Resistance Welding

Resistance welding uses the resistance of an electric current passing through aluminum sheets to generate heat, forming a weld between two sheets. It is suitable for thickened components and applications where minimal distortion is required. However, resistance welding can produce scale, which requires protective treatment and treatment.

Laser Welding

Laser welding uses a high-energy laser beam for welding, offering advantages such as high precision, high quality, and smooth weld surfaces. It is suitable for precision welding of aluminum alloys, but requires expensive equipment and enhanced safety measures.

The above are common welding methods for aluminum profiles. Choosing the appropriate method requires consideration of factors such as the material type, thickness, shape, and intended use. It is also important to use standard welding equipment, shielding gas, and welding materials.

What precautions should be taken before and after aluminum welding

Before Welding1. Cleaning

When cleaning aluminum and aluminum alloys, the weld joint and the welding wire surface must be thoroughly cleaned of oxide films and oil stains before welding.

Chemical Cleaning

Chemical cleaning is highly efficient and provides consistent quality, making it suitable for cleaning welding wire and smaller, batch-produced workpieces. Both immersion and scrubbing methods can be used. Surface degreasing can be achieved with organic solvents such as acetone, gasoline, and kerosene. Alkaline cleaning with a 5% to 10% NaOH solution at 40°C to 70°C for 3 to 7 minutes (for pure aluminum, the time may be slightly longer, but no more than 20 minutes), followed by rinsing with running water. Followed by an acid clean with a 30% HNO₃ solution at room temperature to 60°C for 1 to 3 minutes, followed by rinsing with running water, and air drying or low-temperature drying.

Mechanical Cleaning

Mechanical cleaning is often used for larger workpieces, longer production cycles, or when contamination persists after multiple welding cycles or chemical cleaning. First, wipe the surface with an organic solvent, such as acetone or gasoline, to remove any oil. Then, directly brush with a copper or stainless steel wire brush (0.15 mm to 0.2 mm in diameter) until the metallic luster is revealed. Grinding with a grinding wheel or ordinary sandpaper is generally not recommended to prevent sand particles from remaining on the metal surface and entering the molten pool during welding, causing defects such as slag inclusions. Alternatively, a scraper or file can be used to clean the surface to be welded.

After cleaning: If the material has been stored for an extended period (e.g., over 24 hours), it should be reprocessed.

2. Backing Plate

Aluminum alloys have very low strength at high temperatures, and liquid aluminum has good fluidity, making weld metal prone to collapse during welding. To ensure full penetration without collapse, a backing plate is often used to support the molten pool and surrounding metal. Backing plates can be made of graphite, stainless steel, carbon steel, copper, or copper rod. A circular groove is cut into the backing plate's surface to ensure the weld's reverse side is formed. Single-sided welding and double-sided forming are also possible without a backing plate, but this requires skilled welding skills or the use of advanced process measures such as strict automatic feedback control of arc energy.

3. Preheating Before Welding

Thin and small aluminum parts generally do not require preheating. Preheating is acceptable for parts with a thickness of 10 mm to 15 mm. Depending on the type of aluminum alloy, the preheating temperature can range from 100°C to 200°C. Heating can be done with an oxyacetylene flame, electric furnace, or blowtorch. Preheating can minimize deformation and defects such as porosity in the weld.

Post-weld Treatment

1. Residual flux and slag left in and around the weld seam after welding can damage the passivation film on the aluminum surface and sometimes corrode the aluminum part. They should be cleaned. Simple workpieces with general requirements can be cleaned with simple methods such as hot water flushing or steam blasting. For aluminum parts with complex shapes and high requirements, scrub them in hot water with a stiff brush, then immerse them in a 2% to 3% aqueous chromic anhydride or potassium dichromate solution at approximately 60°C to 80°C for 5 to 10 minutes. Rinse with a stiff brush, rinse in hot water, and dry in an oven, hot air, or naturally.

2. Post-weld heat treatment: Aluminum containers generally do not require heat treatment after welding.

If welding is not an option, what are some alternatives?

With advances in production technology, many aluminum profiles can now be assembled and used without requiring welding. The following are some common alternatives to welding for aluminum:

Mechanical connections (angle brackets, screws, rivets) → High strength and removable;

Gluing/structural adhesives → Aesthetically pleasing and airtight;

Plug-in/clip-on connections → Quick assembly, suitable for furniture and display structures.

In the window, door, and curtain wall industries, the most commonly used method is angle brackets combined with structural adhesives, which have virtually replaced welding.

Generally, the decision to weld aluminum extrusions depends on the profile, application scenario, and specific needs. Our aluminum extrusion manufacturers typically support welding, bending, cutting, and other processing techniques, primarily based on customer needs and our own production experience. If you're interested in understanding other advanced processing techniques beyond aluminum extrusion welding, please contact us for a technical guide to advanced processing techniques.