Aluminum Frame For Solar Panel Is The Best Choice

Updated: 7 Jul 2025

Aluminum is the most abundant metal on earth. Aluminum alloy is composed of aluminum and incorporates a specific amount of other alloying elements. It possesses many excellent properties and is widely utilized in industry and daily life. Aluminum alloy frames have long been a crucial auxiliary material for solar panel, and their development has closely followed the growth of the photovoltaic industry.

As the second-largest structural material, aluminum alloy exhibits excellent properties: high strength, firmness, good conductivity, corrosion resistance, oxidation resistance, strong tensile strength, convenient transportation and installation, and easy recycling, which are unmatched by other materials. Since the advent of photovoltaic modules, they have been used as a frame material and have been a constant companion. There is no other material to replace it. It withstands the wind and snow resistance of photovoltaic modules, providing all-around protection for them and facilitating the installation of these modules. It is enough to show the irreplaceable nature of aluminum frames in solar panel.

.jpg)

1. Low density, the density of aluminum is about 2.7g/cm³, the second lightest metal in metal structural materials, only higher than magnesium, and only 1/3 of iron or copper;

2. Easy to strengthen, pure aluminum has low strength, but it can be easily strengthened through alloying and heat treatment to make high-strength aluminum alloy, the strength of which can be comparable to that of alloy steel, so the elastic modulus, rigidity, and metal fatigue value are high, not easy to deform, and can well protect solar panels;

3. Good electrical conductivity, the electrical conductivity and thermal conductivity of aluminum are second only to silver, gold, and copper. If calculated according to the conductivity of metals of equal mass, aluminum is almost twice that of copper. Therefore, it is conducive to the grounding of component installation.

4. High plasticity, aluminum and its alloys have good ductility, and can be made into various types, plates, foils, tubes and wires through pressure processing methods such as extrusion, rolling or drawing;

5. Easy surface treatment, aluminum can be treated by anodizing and coloring, and the hardness is increased after treatment, providing good wear resistance, corrosion resistance, and electrical insulation. Through chemical pretreatment, electroplating, electrophoresis, spraying, etc., can also be performed to further improve the decorative and protective properties of aluminum;

6. Aluminum and oxygen have an extremely high affinity, and protective oxides form on the surface of aluminum under natural conditions, resulting in stronger corrosion resistance than steel. Because of this advantage, aluminum alloy profiles are widely used in various fields of construction and industry;

7. Convenient transportation and installation, even if the surface is scratched, it will not produce oxidation and will not affect the performance;

8. Long service life, the life of aluminum alloy is generally more than 30-50 years. The lifespan of a solar panel is 25-30 years, ensuring it can fully meet the usage requirements.

9. Beautiful appearance: After the aluminum alloy surface is treated with anodizing, it can present silver, black, or other colors, meeting aesthetic requirements.

10. Easy to recycle, the melting temperature of aluminum is low, approximately 660°C. Waste is easily regenerated, with an extremely high recycling rate, and the energy consumption required for recycling is only 3% of the original aluminum.

In response to the two major development goals of “cost reduction” and “efficiency increase” in the photovoltaic industry, most component manufacturers employ various solutions to reduce component costs and enhance efficiency, such as lowering glass thickness, decreasing silicon wafer thickness, and increasing component size. The above cost reduction solutions ultimately put forward higher requirements on the strength of the frame structure.

In response to the two major development goals of “cost reduction” and “efficiency increase” in the photovoltaic industry, most component manufacturers employ various solutions to reduce component costs and enhance efficiency, such as lowering glass thickness, decreasing silicon wafer thickness, and increasing component size. The above cost reduction solutions ultimately put forward higher requirements on the strength of the frame structure.

At the same time, photovoltaic component manufacturers have been seeking alternative solutions, including frameless double-glass components that eliminate frames, and have also considered using other materials for photovoltaic frames, such as steel structures, rubber, and composite materials.

However, through continuous experiments and comparisons, it has been concluded that aluminum alloy is the best choice for the photovoltaic industry. Aluminum frames are used in the photovoltaic industry, which not only protects photovoltaic cells but also increases their service life. Even if exposed to harsh environments for a long time, aluminum solar panel remain good.

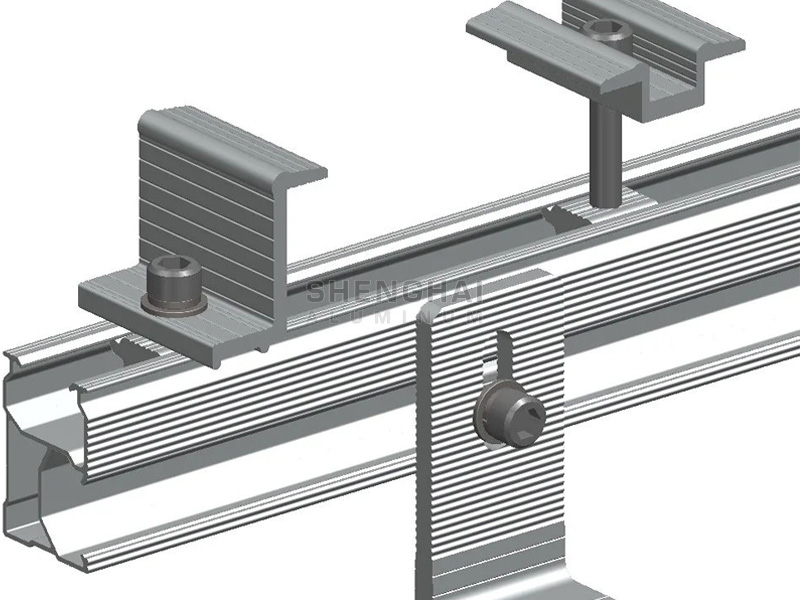

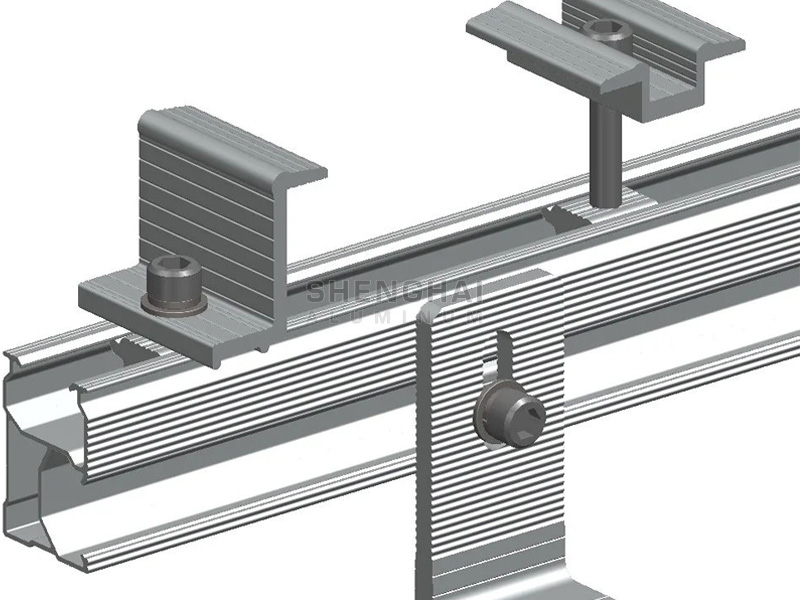

In addition to aluminum frames for solar panels, we also offer a range of photovoltaic aluminum accessories, including aluminum solar rails, aluminum solar clamps, and rail ingot kits. To obtain aluminum solar panel solutions, please don’t hesitate to contact us for complimentary samples and quotes.

As the second-largest structural material, aluminum alloy exhibits excellent properties: high strength, firmness, good conductivity, corrosion resistance, oxidation resistance, strong tensile strength, convenient transportation and installation, and easy recycling, which are unmatched by other materials. Since the advent of photovoltaic modules, they have been used as a frame material and have been a constant companion. There is no other material to replace it. It withstands the wind and snow resistance of photovoltaic modules, providing all-around protection for them and facilitating the installation of these modules. It is enough to show the irreplaceable nature of aluminum frames in solar panel.

.jpg)

Features of Aluminum Solar Frame

Aluminum alloy frame has always been one of the indispensable auxiliary materials for solar panel, mainly due to the advantages of aluminum alloy materials themselves, mainly including:1. Low density, the density of aluminum is about 2.7g/cm³, the second lightest metal in metal structural materials, only higher than magnesium, and only 1/3 of iron or copper;

2. Easy to strengthen, pure aluminum has low strength, but it can be easily strengthened through alloying and heat treatment to make high-strength aluminum alloy, the strength of which can be comparable to that of alloy steel, so the elastic modulus, rigidity, and metal fatigue value are high, not easy to deform, and can well protect solar panels;

3. Good electrical conductivity, the electrical conductivity and thermal conductivity of aluminum are second only to silver, gold, and copper. If calculated according to the conductivity of metals of equal mass, aluminum is almost twice that of copper. Therefore, it is conducive to the grounding of component installation.

4. High plasticity, aluminum and its alloys have good ductility, and can be made into various types, plates, foils, tubes and wires through pressure processing methods such as extrusion, rolling or drawing;

5. Easy surface treatment, aluminum can be treated by anodizing and coloring, and the hardness is increased after treatment, providing good wear resistance, corrosion resistance, and electrical insulation. Through chemical pretreatment, electroplating, electrophoresis, spraying, etc., can also be performed to further improve the decorative and protective properties of aluminum;

6. Aluminum and oxygen have an extremely high affinity, and protective oxides form on the surface of aluminum under natural conditions, resulting in stronger corrosion resistance than steel. Because of this advantage, aluminum alloy profiles are widely used in various fields of construction and industry;

7. Convenient transportation and installation, even if the surface is scratched, it will not produce oxidation and will not affect the performance;

8. Long service life, the life of aluminum alloy is generally more than 30-50 years. The lifespan of a solar panel is 25-30 years, ensuring it can fully meet the usage requirements.

9. Beautiful appearance: After the aluminum alloy surface is treated with anodizing, it can present silver, black, or other colors, meeting aesthetic requirements.

10. Easy to recycle, the melting temperature of aluminum is low, approximately 660°C. Waste is easily regenerated, with an extremely high recycling rate, and the energy consumption required for recycling is only 3% of the original aluminum.

At the same time, photovoltaic component manufacturers have been seeking alternative solutions, including frameless double-glass components that eliminate frames, and have also considered using other materials for photovoltaic frames, such as steel structures, rubber, and composite materials.

However, through continuous experiments and comparisons, it has been concluded that aluminum alloy is the best choice for the photovoltaic industry. Aluminum frames are used in the photovoltaic industry, which not only protects photovoltaic cells but also increases their service life. Even if exposed to harsh environments for a long time, aluminum solar panel remain good.

In addition to aluminum frames for solar panels, we also offer a range of photovoltaic aluminum accessories, including aluminum solar rails, aluminum solar clamps, and rail ingot kits. To obtain aluminum solar panel solutions, please don’t hesitate to contact us for complimentary samples and quotes.