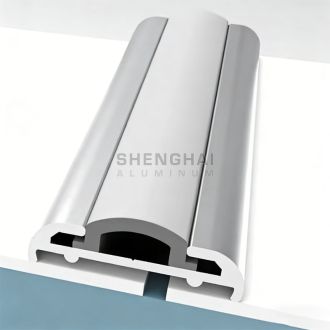

RV Aluminum Trailer Trim Molding

Place of Origin:

Guangdong, China (Mainland)

Grade:

6000 Series

Temper:

T3-T8

Application:

Decorations

Shape:

Angle

Alloy Or Not:

Is Alloy

Brand Name:

shenghai

Precision:

+-5%

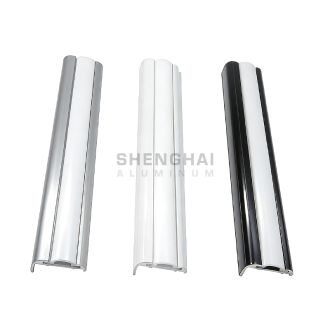

Surface Treatment:

Mill finish, powder coated, anodized, electrophoresis, Polishing

Thickness:

0.6mm-2.0mm

Machining:

High Precision CNC Machining

Deep Process:

Precise cutting, drilling, milling, fabricating

Quality Standard:

GB 5237-2008

Product Description

Aluminum trim molding is designed to provide both structural reinforcement and long-term weather protection for RVs and trailers. These RV aluminum trailer trim moldings are widely used for roof edges, corners, seams, gutters, and awning systems, helping create a clean, finished exterior while enhancing overall durability. Corner and flat trim profiles strengthen panel connections and effectively seal joints, reducing vibration and preventing water ingress. Integrated gutter and drip rail designs guide rainwater away from side walls, minimizing water stains and potential leakage issues. Awning rails are precisely engineered with smooth channels to securely hold awning fabric, ensuring reliable operation during extension and retraction. Available in mill finish, anodized surfaces, and customizable colors or finishes, RV aluminum trailer trim molding offers a practical, corrosion-resistant solution for RV manufacturing, exterior upgrades, and replacement applications.RV Aluminum Trailer Trim - FAQS

1. What surface finishes are available?Standard finishes include mill finish and anodized aluminum. For project-based or brand-specific needs, powder coating and color-matched finishes can be provided to ensure consistency with the RV or trailer exterior.

2. How does aluminum trim help with water resistance and sealing?

Properly designed trim molding reinforces joints and transitions while sealing panel gaps, reducing the risk of water intrusion. Gutter and drip rail profiles are specifically engineered to direct rainwater away from side panels, helping prevent leaks and water damage.

3. Is RV aluminum trailer trim molding suitable for outdoor and long-term use?

Yes. Aluminum trim moldings offer excellent corrosion resistance, UV stability, and weather durability, making them suitable for long-term outdoor exposure in various climates.

4. How is the price calculated?

Pricing depends on profile design, aluminum alloy, wall thickness, surface finish, order quantity, and length. Custom profiles are quoted separately with a one-time tooling cost.

5. What is the MOQ for ordering?

Custom RV aluminum trailer trim molding requires MOQ based on profile complexity and production volume.

6. Can samples be provided before bulk orders?

Yes, we can provide samples.

7. What information is needed for a quotation?

For accurate pricing, please provide profile drawings or reference photos, application, surface finish requirements, and estimated order quantity.

Product Application

Our Factory

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Get a Quote