Top-rated Aluminium Profile Handles For Modern Kitchens

Updated: 26 Dec 2025

In modern kitchen design, a component that is often overlooked but crucial is the handle. These accessories not only affect their practicality but also directly shape the overall decoration style. When choosing cabinet handles, the material should be the first consideration. Currently, there are many different materials for cabinet handles on the market. Common materials include stainless steel, zinc alloy, plastic, and aluminum alloy. Among them, aluminium handles for kitchen cabinets have attracted much attention for their outstanding durability and beautiful appearance, and have gradually become well-known, making them the first choice for modern kitchen design worldwide.

Straight handle: It features an integrated linear design with neat, smooth lines and no superfluous decoration. It can fit a wide range of cabinet sizes, including base cabinets, wall cabinets, and drawers, easily achieving a unified style for kitchen hardware.

Bending handle: The integrally formed curved structure has no sharp edges or corners, helping prevent bumps and knocks when turning around in a hurry during cooking. Suitable for cabinet doors of stove cabinets and sink cabinets.

C-shaped handle: The classic C-shaped design is simple and practical. It is compact, takes up little space, and can be installed in a damp area near the sink.

Combined handle: It adopts a modular combination design, offering extremely high flexibility. Supports customized surface treatment, suitable for kitchens of various styles. It can be mixed and matched for use in the kitchen, sideboard and entrance cabinet.

Overall, these four mainstream types of aluminum cabinet handles each have their own highlights, being both aesthetically pleasing and practical. Whether it's creating a personalized home kitchen or a commercial dining space that emphasizes safety and high durability, there are suitable options available.

1.Sturdy Structure and Durable Material

In a kitchen used every day, practicality is vital. Aluminum alloy, as a metal material, combines strength and toughness, capable of withstanding considerable force. It is not easy to break or loosen in frequent opening and closing. Shenghai Aluminum uses high-quality 6063 aluminum alloy, which provides excellent structural strength. The surface, after fine grinding and polishing, is smooth and more comfortable to the touch.

The kitchen is a high-intensity area in the home environment, where there are frequent oil fumes and various chemical cleaning products are used. Aluminum profile handles have natural anti-oxidation properties. After anodizing or powder coating, a dense protective film forms on the surface. It can effectively resist corrosion from oil fumes, water vapor, and cleaning agents, and will not experience problems such as rusting or coating peeling. It can maintain a clean appearance and stable structure even after long-term use, and its service life far exceeds that of traditional material handles.

2.Production and Processing Technology

We know that, as an aluminum profile handle manufacturer, both its production and processing capacities are definitely trustworthy. By adopting advanced production equipment and mature production technology, it ensures product quality and delivery time while also saving customers' energy.

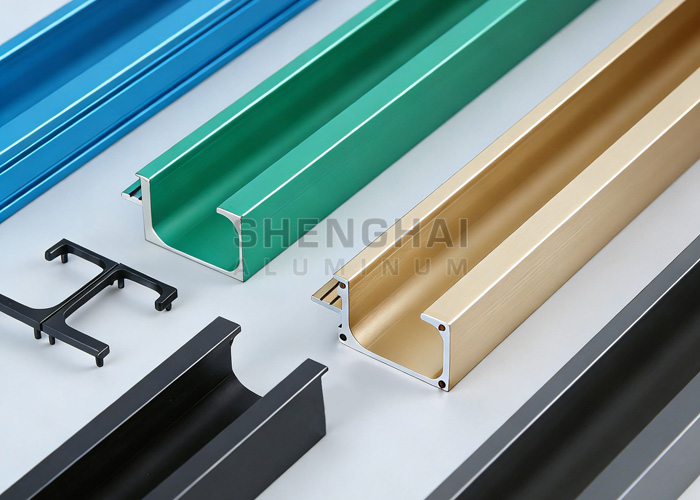

3.Surface Treatment Technology

Aluminum alloy has extremely strong plasticity and surface adaptability. Through various surface treatment processes such as anodizing, powder coating, electrophoresis, and wood grain transfer printing, it can present a wide variety of appearances, including matte metal, bright colors, and realistic wood grain. The surface coating is scratch-resistant, wear-resistant, corrosion-resistant and does not fade, and can maintain its color for a long time.

From the perspective of market prospects, aluminium profile handle kitchen is entering a period of rapid development. Whether in the residential decoration market or in commercial kitchen engineering projects, demand for high-quality aluminum profile handles is increasing year by year, with significant market potential and growth prospects.

Craftsmanship: Handle aluminium kitchen relies on a mature process of "extrusion molding + precision processing", the craftsmanship accuracy reaching the millimeter level. During the production stage, through high-precision mold extrusion, the profile's cross-section is regular, the wall thickness is uniform, and there are no burrs, unevenness, or other defects.

On the contrary, stainless steel handles are durable due to their high material hardness. During processing, stainless steel handles are extremely difficult to bend and to create special shapes. It is very easy to have problems such as protruding weld points, stiff arcs, and even sharp edges and corners. Most of the time, only standardized straight models can be made, and the details of custom models are even rougher.

Plastic handles are entirely made by mold injection molding. Not only are their shapes fixed, but they also often have burrs, shrinkage marks, uneven wall thickness and other problems. Micro-hole offset and rough edges are common issues.

Quality Stability: The performance of handle aluminium kitchen is also very excellent. It uses the industry-recognized 6061 and 6063 aluminum alloys, which offer high strength and good toughness. It will not deform or fall off even if opened and closed frequently over a long period of time. At the same time, because the aluminum profile handle is lightweight, it will not add weight to the cabinet door panel, helping prevent problems such as loose screws over time. Moreover, during mass production, quality consistency is extremely high, so there is no need to worry about significant individual differences in products.

Although stainless steel handles have acceptable strength, their overall weight can, over time, cause the cabinet panels to droop and deform and loosen the door panel screws. Low-priced products have poor composition control, and problems such as soft profiles and imperfect welds often occur.

The performance of plastic handles is even less satisfactory. The material itself has low strength, and internal stress is likely to remain during production. It will be brittle and deformed when subjected to slight stress or impact. The quality of different batches is also unstable, and their lifespan is extremely short.

Texture: Aluminum profile handles in the kitchen are far ahead. The surface treatment process is particularly rich. Anodizing, powder coating, etc., can easily adapt to various decoration styles such as simplicity, light luxury, and sophistication.

The surface treatment of stainless steel handles is much simpler. Most of them are polished or brushed, with a rather cold and hard texture. They are only suitable for a few styles, such as industrial. Bright surface models are easy to leave fingerprints and scratches, while the brushed models look rigid and are difficult to integrate into a warm or light luxury kitchen.

The texture of plastic handles is even cheaper and rougher. The surface has no complex processing, either a single matte or a bright surface. They are prone to scratches and yellowing, and their color also fades easily. Not only do they fail to enhance the kitchen's appearance, but they may also undermine the overall decor style.

Processing Flexibility: The advantages of aluminum cabinet handles are irreplaceable. During the production stage, by simply changing the mold, various basic profiles, such as straight and C-shaped grooves, can be produced. During processing, other special-shaped designs can also be made by bending with a CNC machine. It also supports customization of color, style, and length, fully meeting personalized demands.

Stainless steel handles are hard to work with, and the welding and bending processes are complex and costly. It is extremely difficult to make them into irregular shapes, and the customization cycle is long. There are only a few color options, such as silver and black, and the applicable scenarios are particularly limited.

Plastic handles are completely dependent on molds and can only be made into fixed shapes. They cannot adjust the detailed dimensions or achieve special-shaped designs. It is even more difficult to match their color to the cabinet door panels. Their compatibility is extremely poor.

Durability: Aluminum profile handles kitchen performance particularly well in environments with high oil fumes and water vapor. Aluminum alloy itself is not easy to rust. After undergoing surface treatments such as anodizing and powder coating, a dense protective layer is formed that effectively resists the erosion from oil fumes and water vapor, does not oxidize or fade, and is also resistant to oil stains. It can be cleaned thoroughly with a damp cloth daily. Maintenance is particularly worry-free, and its service life can reach over 20 years.

Although the high-quality 304 and 316 stainless steel handles have good corrosion resistance, the low-priced models are prone to rust, especially at the weld points, which are particularly susceptible to oxidation and corrosion. Moreover, bright surface models are easy to leave fingerprints and scratches, requiring frequent wiping and maintenance with a specific cleaner. Heavy weight will also cause long-term damage to the door panels.

Plastic handles are even less durable. They are not heat-resistant and are easy to aging. Under the erosion of kitchen oil fumes and water vapor, they will quickly turn yellow, crack and become brittle. Once the surface is scratched, it cannot be repaired. Their service life is only 2 to 3 years, and they need to be replaced frequently. The long-term usage cost is even higher.

Therefore, whether it is about pursuing fine craftsmanship, stable quality, valuing texture, ensuring processing compatibility, or considering long-term durability, aluminum handles for kitchen cabinets are a better choice than stainless steel or plastic handles. This is also the core reason it has become the market's preferred choice.

As a professional manufacturer deeply engaged in the field of Aluminum profile handles for kitchen, the core advantage of Shenghai Aluminum lies in: according to the project requirements of customers, a professional team provides customized design support. Whether it's a minimalist, invisible style or a special surface treatment requirement, it can precisely achieve the desired effect. Avoid rework in the later stage caused by design deviations. High-quality aluminum rod extrusion molding controls the material uniformity and structural stability of the profile from the source. Then, through CNC precision processing, bending and other procedures, the details are implemented. Finally, it undergoes strict surface treatment and quality inspection. This integrated model of "design - production - processing - inspection" not only eliminates communication costs across multiple links for customer connection, but also significantly reduces intermediate losses and efficiently aligns project progress through large-scale production and process optimization.

In global project cooperation, Shenghai Aluminum has developed comprehensive capabilities to respond to the differentiated demands of various countries. In response to the coastal environment and the standard hole requirements of South America for the high-end kitchen with a light luxury style in Uruguay, the more corrosion-resistant 6063-T5 aluminum alloy is selected, and a double-layer protection process of anodic oxidation and powder coating is adopted. Under pressure to control costs and deliver batches of fully furnished housing projects in Malaysia, the production cycle is optimized by combining standardized molds with customized processing and parallel production across multiple production lines. Choosing a reliable Aluminum handle supplier like Shenghai Aluminum not only enables you to obtain high-quality products but also provides professional technical support, a stable supply chain, and the impetus for continuous innovation. Save time and costs with one-stop service, helping you reduce production costs and enhance product competitiveness.

In a kitchen, aluminum profile handles are an important element that combines functionality, aesthetic value and durability. Nowadays, the wave of aluminum cabinet handles is underway. This is not only an opportunity to upgrade products, but also a chance for the entire industry to transform. Choosing the kitchen aluminium profile handles from Shenghai Aluminum can give your project a core advantage in terms of quality, efficiency, and cost, and help it stand out in fierce market competition.

Aluminum handles are sturdy and durable, and highly customizable in style and color. Shenghai Aluminum, a brand with many years of industry experience, has always placed products and services at the foundation of its operations. You can find the most suitable aluminum cabinet handle for your project at Shenghai Aluminum. Welcome to contact us at any time. We will provide you with professional solutions.

What Are The Most Popular Types of Aluminum Handles for Kitchen

Aluminum cabinet handles come in a wide variety of styles and can precisely match different kitchen design styles and usage scenarios. Currently, the four most popular types on the market are as follows:Straight handle: It features an integrated linear design with neat, smooth lines and no superfluous decoration. It can fit a wide range of cabinet sizes, including base cabinets, wall cabinets, and drawers, easily achieving a unified style for kitchen hardware.

Bending handle: The integrally formed curved structure has no sharp edges or corners, helping prevent bumps and knocks when turning around in a hurry during cooking. Suitable for cabinet doors of stove cabinets and sink cabinets.

C-shaped handle: The classic C-shaped design is simple and practical. It is compact, takes up little space, and can be installed in a damp area near the sink.

Combined handle: It adopts a modular combination design, offering extremely high flexibility. Supports customized surface treatment, suitable for kitchens of various styles. It can be mixed and matched for use in the kitchen, sideboard and entrance cabinet.

Overall, these four mainstream types of aluminum cabinet handles each have their own highlights, being both aesthetically pleasing and practical. Whether it's creating a personalized home kitchen or a commercial dining space that emphasizes safety and high durability, there are suitable options available.

Why Are Aluminum Kitchen Cabinet Handles Top-rated

The reason why aluminium profile handle kitchen have become the "top trend" in the market lies in their exquisite production techniques, high-quality base materials and diverse design styles, as well as their processing advantages that can adapt to multiple styles. Compared with stainless steel and plastic handles, it offers all-around advantages, precisely meeting modern kitchens' demands for "high-end, simple and light luxury", and has become the preferred accessory for many aluminum cabinet companies. The following are the advantages of aluminum cabinet handles:1.Sturdy Structure and Durable Material

In a kitchen used every day, practicality is vital. Aluminum alloy, as a metal material, combines strength and toughness, capable of withstanding considerable force. It is not easy to break or loosen in frequent opening and closing. Shenghai Aluminum uses high-quality 6063 aluminum alloy, which provides excellent structural strength. The surface, after fine grinding and polishing, is smooth and more comfortable to the touch.

The kitchen is a high-intensity area in the home environment, where there are frequent oil fumes and various chemical cleaning products are used. Aluminum profile handles have natural anti-oxidation properties. After anodizing or powder coating, a dense protective film forms on the surface. It can effectively resist corrosion from oil fumes, water vapor, and cleaning agents, and will not experience problems such as rusting or coating peeling. It can maintain a clean appearance and stable structure even after long-term use, and its service life far exceeds that of traditional material handles.

2.Production and Processing Technology

We know that, as an aluminum profile handle manufacturer, both its production and processing capacities are definitely trustworthy. By adopting advanced production equipment and mature production technology, it ensures product quality and delivery time while also saving customers' energy.

3.Surface Treatment Technology

Aluminum alloy has extremely strong plasticity and surface adaptability. Through various surface treatment processes such as anodizing, powder coating, electrophoresis, and wood grain transfer printing, it can present a wide variety of appearances, including matte metal, bright colors, and realistic wood grain. The surface coating is scratch-resistant, wear-resistant, corrosion-resistant and does not fade, and can maintain its color for a long time.

From the perspective of market prospects, aluminium profile handle kitchen is entering a period of rapid development. Whether in the residential decoration market or in commercial kitchen engineering projects, demand for high-quality aluminum profile handles is increasing year by year, with significant market potential and growth prospects.

Aluminum Alloy Handles VS Stainless Steel & Plastic Handles

In the cabinet handle market, aluminum profile handles, thanks to their material characteristics and technological advantages, comprehensively outperform stainless steel and plastic handles in key dimensions such as craftsmanship, quality, texture, processing flexibility, and durability, making them the top choice for modern kitchen demands. Next, we will make a detailed comparison of aluminum profile handles with stainless steel and plastic handles from the following aspects:Craftsmanship: Handle aluminium kitchen relies on a mature process of "extrusion molding + precision processing", the craftsmanship accuracy reaching the millimeter level. During the production stage, through high-precision mold extrusion, the profile's cross-section is regular, the wall thickness is uniform, and there are no burrs, unevenness, or other defects.

On the contrary, stainless steel handles are durable due to their high material hardness. During processing, stainless steel handles are extremely difficult to bend and to create special shapes. It is very easy to have problems such as protruding weld points, stiff arcs, and even sharp edges and corners. Most of the time, only standardized straight models can be made, and the details of custom models are even rougher.

Plastic handles are entirely made by mold injection molding. Not only are their shapes fixed, but they also often have burrs, shrinkage marks, uneven wall thickness and other problems. Micro-hole offset and rough edges are common issues.

Quality Stability: The performance of handle aluminium kitchen is also very excellent. It uses the industry-recognized 6061 and 6063 aluminum alloys, which offer high strength and good toughness. It will not deform or fall off even if opened and closed frequently over a long period of time. At the same time, because the aluminum profile handle is lightweight, it will not add weight to the cabinet door panel, helping prevent problems such as loose screws over time. Moreover, during mass production, quality consistency is extremely high, so there is no need to worry about significant individual differences in products.

Although stainless steel handles have acceptable strength, their overall weight can, over time, cause the cabinet panels to droop and deform and loosen the door panel screws. Low-priced products have poor composition control, and problems such as soft profiles and imperfect welds often occur.

The performance of plastic handles is even less satisfactory. The material itself has low strength, and internal stress is likely to remain during production. It will be brittle and deformed when subjected to slight stress or impact. The quality of different batches is also unstable, and their lifespan is extremely short.

Texture: Aluminum profile handles in the kitchen are far ahead. The surface treatment process is particularly rich. Anodizing, powder coating, etc., can easily adapt to various decoration styles such as simplicity, light luxury, and sophistication.

The surface treatment of stainless steel handles is much simpler. Most of them are polished or brushed, with a rather cold and hard texture. They are only suitable for a few styles, such as industrial. Bright surface models are easy to leave fingerprints and scratches, while the brushed models look rigid and are difficult to integrate into a warm or light luxury kitchen.

The texture of plastic handles is even cheaper and rougher. The surface has no complex processing, either a single matte or a bright surface. They are prone to scratches and yellowing, and their color also fades easily. Not only do they fail to enhance the kitchen's appearance, but they may also undermine the overall decor style.

Processing Flexibility: The advantages of aluminum cabinet handles are irreplaceable. During the production stage, by simply changing the mold, various basic profiles, such as straight and C-shaped grooves, can be produced. During processing, other special-shaped designs can also be made by bending with a CNC machine. It also supports customization of color, style, and length, fully meeting personalized demands.

Stainless steel handles are hard to work with, and the welding and bending processes are complex and costly. It is extremely difficult to make them into irregular shapes, and the customization cycle is long. There are only a few color options, such as silver and black, and the applicable scenarios are particularly limited.

Plastic handles are completely dependent on molds and can only be made into fixed shapes. They cannot adjust the detailed dimensions or achieve special-shaped designs. It is even more difficult to match their color to the cabinet door panels. Their compatibility is extremely poor.

Durability: Aluminum profile handles kitchen performance particularly well in environments with high oil fumes and water vapor. Aluminum alloy itself is not easy to rust. After undergoing surface treatments such as anodizing and powder coating, a dense protective layer is formed that effectively resists the erosion from oil fumes and water vapor, does not oxidize or fade, and is also resistant to oil stains. It can be cleaned thoroughly with a damp cloth daily. Maintenance is particularly worry-free, and its service life can reach over 20 years.

Although the high-quality 304 and 316 stainless steel handles have good corrosion resistance, the low-priced models are prone to rust, especially at the weld points, which are particularly susceptible to oxidation and corrosion. Moreover, bright surface models are easy to leave fingerprints and scratches, requiring frequent wiping and maintenance with a specific cleaner. Heavy weight will also cause long-term damage to the door panels.

Plastic handles are even less durable. They are not heat-resistant and are easy to aging. Under the erosion of kitchen oil fumes and water vapor, they will quickly turn yellow, crack and become brittle. Once the surface is scratched, it cannot be repaired. Their service life is only 2 to 3 years, and they need to be replaced frequently. The long-term usage cost is even higher.

Therefore, whether it is about pursuing fine craftsmanship, stable quality, valuing texture, ensuring processing compatibility, or considering long-term durability, aluminum handles for kitchen cabinets are a better choice than stainless steel or plastic handles. This is also the core reason it has become the market's preferred choice.

Choose A Good Aluminum Handle Supplier To Support Your Project

In today's highly competitive market, choosing a reliable aluminum handle supplier can provide one-stop service, covering the entire chain from drawing design to finished product delivery. First, it ensures that the product's quality aligns with the style. Then it can reduce production costs at the source, enabling your project to achieve a triple improvement in quality, efficiency, and cost performance. And Shenghai Aluminum is such a supplier with both strength and experience.As a professional manufacturer deeply engaged in the field of Aluminum profile handles for kitchen, the core advantage of Shenghai Aluminum lies in: according to the project requirements of customers, a professional team provides customized design support. Whether it's a minimalist, invisible style or a special surface treatment requirement, it can precisely achieve the desired effect. Avoid rework in the later stage caused by design deviations. High-quality aluminum rod extrusion molding controls the material uniformity and structural stability of the profile from the source. Then, through CNC precision processing, bending and other procedures, the details are implemented. Finally, it undergoes strict surface treatment and quality inspection. This integrated model of "design - production - processing - inspection" not only eliminates communication costs across multiple links for customer connection, but also significantly reduces intermediate losses and efficiently aligns project progress through large-scale production and process optimization.

In global project cooperation, Shenghai Aluminum has developed comprehensive capabilities to respond to the differentiated demands of various countries. In response to the coastal environment and the standard hole requirements of South America for the high-end kitchen with a light luxury style in Uruguay, the more corrosion-resistant 6063-T5 aluminum alloy is selected, and a double-layer protection process of anodic oxidation and powder coating is adopted. Under pressure to control costs and deliver batches of fully furnished housing projects in Malaysia, the production cycle is optimized by combining standardized molds with customized processing and parallel production across multiple production lines. Choosing a reliable Aluminum handle supplier like Shenghai Aluminum not only enables you to obtain high-quality products but also provides professional technical support, a stable supply chain, and the impetus for continuous innovation. Save time and costs with one-stop service, helping you reduce production costs and enhance product competitiveness.

In a kitchen, aluminum profile handles are an important element that combines functionality, aesthetic value and durability. Nowadays, the wave of aluminum cabinet handles is underway. This is not only an opportunity to upgrade products, but also a chance for the entire industry to transform. Choosing the kitchen aluminium profile handles from Shenghai Aluminum can give your project a core advantage in terms of quality, efficiency, and cost, and help it stand out in fierce market competition.

Aluminum handles are sturdy and durable, and highly customizable in style and color. Shenghai Aluminum, a brand with many years of industry experience, has always placed products and services at the foundation of its operations. You can find the most suitable aluminum cabinet handle for your project at Shenghai Aluminum. Welcome to contact us at any time. We will provide you with professional solutions.