Aluminum Conductive Oxidation VS Anodized

Updated: 26 Jun 2024

Aluminum alloy is a commonly used metal material with good electrical conductivity. Two processes, conductive oxidation and anodizing, can further improve aluminum alloy's electrical conductivity and corrosion resistance.

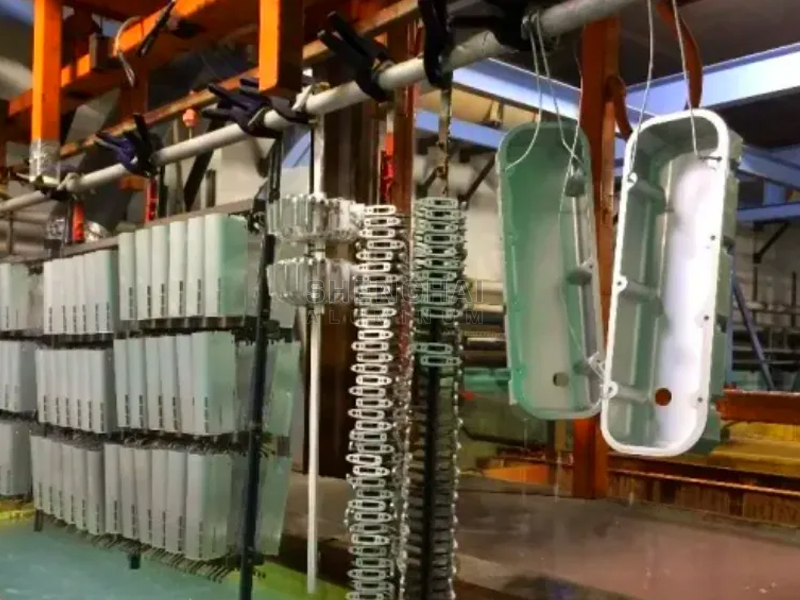

The process flow of conductive oxidation generally includes the following steps:

Surface treatment: First, the surface of the aluminum alloy needs to be cleaned and degreased to ensure the quality of the oxide film.

Oxidation treatment: The aluminum alloy is immersed in an electrolyte containing an oxidant, and a dense oxide film is formed on its surface after a certain potential and time control.

Sealing treatment: Finally, the oxide film is sealed to improve its corrosion resistance and insulation properties.

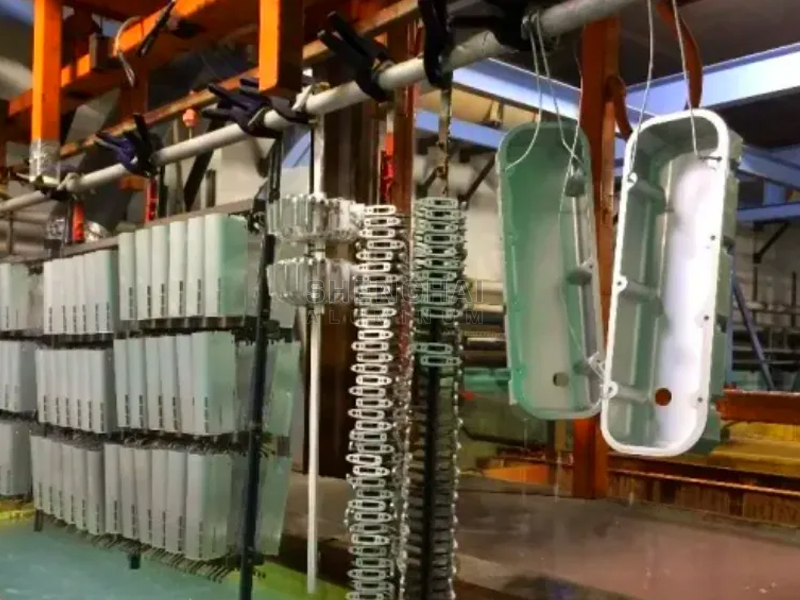

The process flow of anodizing generally includes the following steps:

Surface treatment: First, the surface of the aluminum alloy needs to be cleaned and degreased to ensure the quality of the oxide film.

Anodized treatment: The aluminum alloy is immersed in an electrolyte containing an oxidant, and a thicker oxide film is formed on its surface after a certain potential and time control.

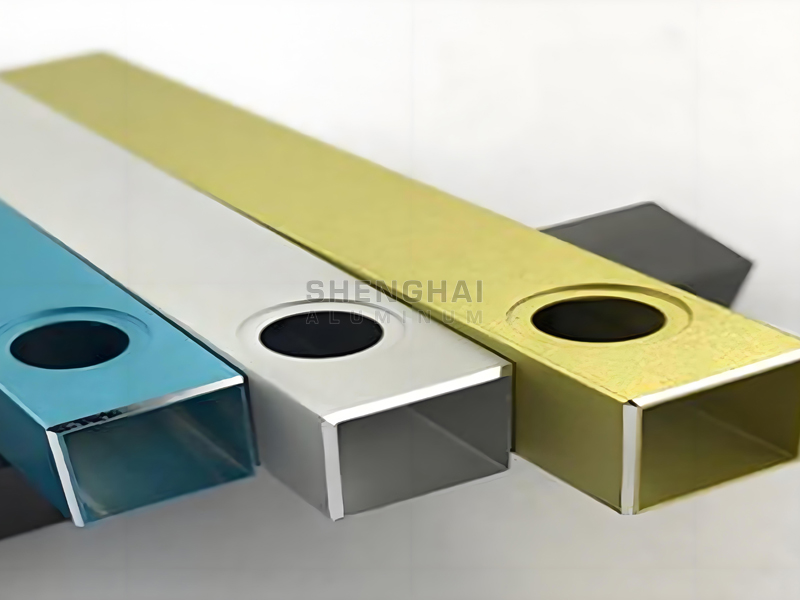

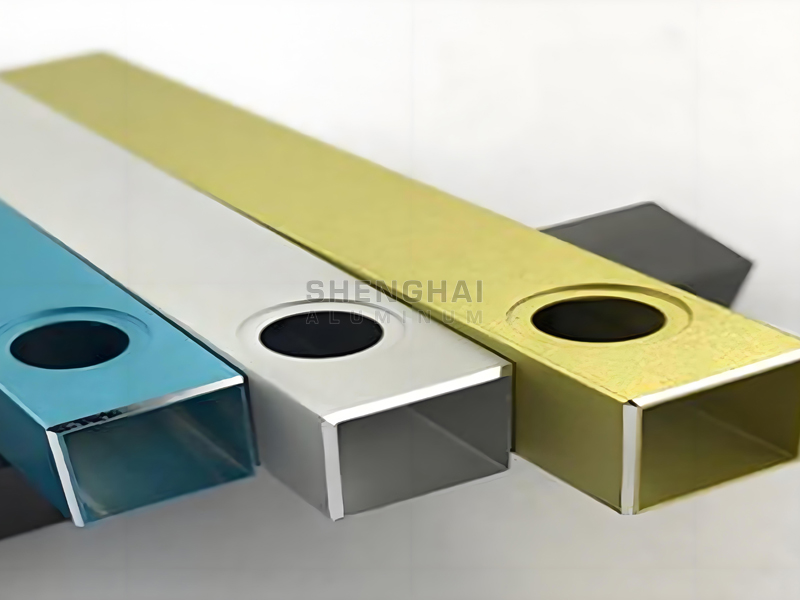

Dyeing treatment (optional): Dyeing treatment can be performed on the formed oxide film to obtain different color effects.

Sealing treatment: Finally, the oxide film is sealed to improve its corrosion resistance and insulation properties.

Conductive oxidation and anodizing processes can effectively improve the performance of aluminum alloys and expand their application range. These processes can improve the conductivity and corrosion resistance of aluminum alloys and give them more aesthetic effects to meet the needs of different fields. In industrial manufacturing, architectural decoration, aerospace, etc., aluminum alloys' conductive oxidation and anodizing processes play an important role.

The difference between aluminum anodizing and conductive oxidation:

The difference between aluminum anodizing and conductive oxidation:

1. Anodizing is carried out when the aluminum profile is soaked in a chemical solution and electrified. It is an electrochemical reaction process; while conductive oxidation (also called chemical oxidation) does not require electrification, it only needs to be soaked in the solution for a while; it is a pure chemical reaction.

2. The film generated by anodizing is a few microns to dozens of microns and is hard and wear-resistant; the oxide film generated by conductive oxidation is only 0.01-0.15 microns, and the wear resistance is not very good. It can conduct electricity and is more corrosion-resistant than the material.

3. Aluminum profile anodizing takes a long time, and a set of processes takes dozens of minutes; conductive oxidation is very fast, only a dozen seconds.

Therefore, whether aluminum profiles choose conductive oxidation or anodizing can be selected according to actual needs. If conductivity is required, a conductive oxidation process should be adopted. Different aluminum processing processes will have different final uses for the product. Therefore, according to the actual needs of the product, choose the correct processing process.

Therefore, whether aluminum profiles choose conductive oxidation or anodizing can be selected according to actual needs. If conductivity is required, a conductive oxidation process should be adopted. Different aluminum processing processes will have different final uses for the product. Therefore, according to the actual needs of the product, choose the correct processing process.

Aluminum Conductive Oxidation Process

Conductive oxidation refers to improving the electrical conductivity of aluminum alloy by forming a dense oxide film on the surface of aluminum alloy. This oxide film is usually composed of aluminum oxide (Al2O3) and has high hardness and insulation properties. It can effectively prevent the aluminum alloy from contacting the external environment and avoid oxidation and corrosion.The process flow of conductive oxidation generally includes the following steps:

Surface treatment: First, the surface of the aluminum alloy needs to be cleaned and degreased to ensure the quality of the oxide film.

Oxidation treatment: The aluminum alloy is immersed in an electrolyte containing an oxidant, and a dense oxide film is formed on its surface after a certain potential and time control.

Sealing treatment: Finally, the oxide film is sealed to improve its corrosion resistance and insulation properties.

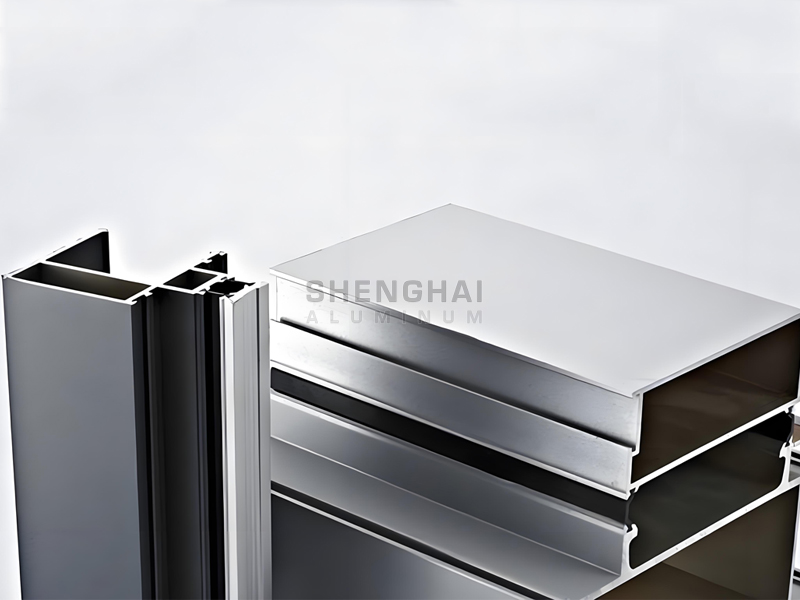

Aluminum Anodized Process

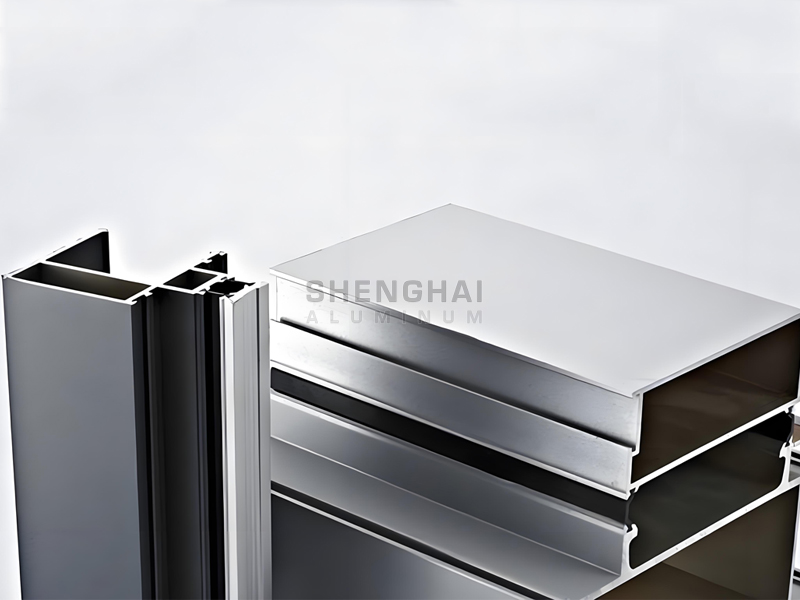

Anodizing is a process that forms a thick oxide film on the surface of aluminum alloy to enhance its wear resistance and corrosion resistance. This oxide film is usually composed of aluminum oxide (Al2O3), has high hardness and insulation properties, and can obtain different color effects by adjusting process parameters.The process flow of anodizing generally includes the following steps:

Surface treatment: First, the surface of the aluminum alloy needs to be cleaned and degreased to ensure the quality of the oxide film.

Anodized treatment: The aluminum alloy is immersed in an electrolyte containing an oxidant, and a thicker oxide film is formed on its surface after a certain potential and time control.

Dyeing treatment (optional): Dyeing treatment can be performed on the formed oxide film to obtain different color effects.

Sealing treatment: Finally, the oxide film is sealed to improve its corrosion resistance and insulation properties.

1. Anodizing is carried out when the aluminum profile is soaked in a chemical solution and electrified. It is an electrochemical reaction process; while conductive oxidation (also called chemical oxidation) does not require electrification, it only needs to be soaked in the solution for a while; it is a pure chemical reaction.

2. The film generated by anodizing is a few microns to dozens of microns and is hard and wear-resistant; the oxide film generated by conductive oxidation is only 0.01-0.15 microns, and the wear resistance is not very good. It can conduct electricity and is more corrosion-resistant than the material.

3. Aluminum profile anodizing takes a long time, and a set of processes takes dozens of minutes; conductive oxidation is very fast, only a dozen seconds.